- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Drying Methods on Total Organic Acid Content of Total Flavonoids from Fructus Corni

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Drying Methods on Total Organic Acid Content of Total Flavonoids from Fructus Corni

2018-11-01 10:15:35

Abstract: The effects of four kinds of microwave drying equipment on total flavonoids, total organic acids, vitamin C and color of hawthorn were studied, and the suitable drying methods of hawthorn were studied. Using hyperoside as standard, the content of total flavonoids in four kinds of drying methods was determined by colorimetric method. The total organic acid content in four kinds of drying methods was determined by acid-base titration with phenolphthalein as indicator. The content of vitamin C in hawthorn was determined by 2,6-dichlorophenol titration method. The color data of four kinds of dry hawthorn powder were determined by colorimeter.

The results showed that the contents of total organic acids, total flavonoids and vitamin C in the four drying methods were significant. The total organic acid and vitamin C content of the freeze-dried samples were the highest, respectively 133. 25 mg / g and 0. 322 4 mg / g; the lowest in natural drying, 94. 55 mg / g and 0. 163 1 mg / g. The content of total flavonoids in microwave drying samples was the highest, and the content of naturally dried samples was the lowest, respectively. 26 mg / g and 32. 25 mg / g. In terms of color, vacuum freeze-dried hawthorn has the best color. Vacuum freeze-drying, on the basis of maximally retaining vitamin C, reduced the loss of total flavonoids to a certain extent and exhibited the most desirable color.

Key words: hawthorn microwave drying; total flavonoids; total organic acid; vitamin C; color

Hawthorn is a dry mature fruit of the genus Crataegus pinnatifida var. major N. E. Br. or Crateagus pinnatifida Bge. It has the functions of digestion and stomach, qi and phlegm, turbidity and lipid-lowering, etc. It can be used for the treatment of meat stagnation syndrome, diarrhea, abdominal pain, belching pain, stagnation of abdominal pain, chest pain, incomplete dysmenorrhea, dysmenorrhea, vomiting blood, blood in the stool, etc. It is indicated that hawthorn mainly contains flavonoids, oligomeric flavans, organic acids, triterpenoids, steroids and organic amines, and its organic acids and flavonoids promote digestion and myocardial ischemia. There are strong pharmacological effects in terms of aspects.

Production processing is an important part of the production and quality of medicinal materials, and drying is one of the key links in the processing of production areas. Appropriate drying method can effectively promote the maximum retention of efficacious substances and nutrients, as well as the separation of medicinal and non-medicinal parts, and can realize the mutual transformation between various chemical components, and finally produce the effectiveness and safety in one. The quality of the medicine.

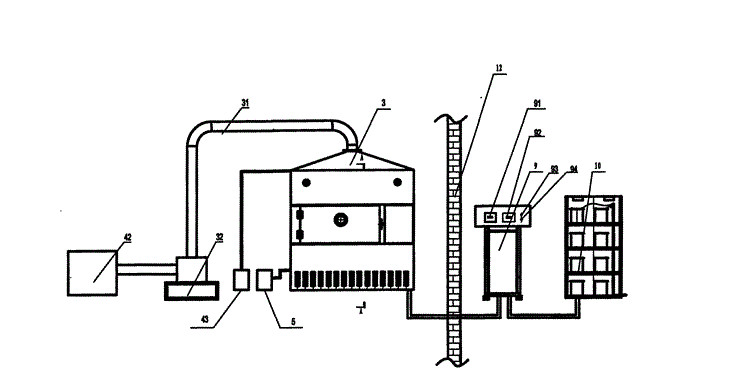

At present, research on hawthorn has focused on chemical composition, pharmacological action and extraction process, and studies on drying methods have not been reported. In this experiment, the hawthorn samples treated by natural drying, oven drying, vacuum freeze drying and microwave drying were studied. The total flavonoids, total organic acids, vitamin C and color indicators were studied to explore the effect of drying methods on the quality of hawthorn. In order to provide data support for the study of drying methods of hawthorn origin.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply