- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research status of drying technology for green leafy vegetables

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research status of drying technology for green leafy vegetables

2018-11-01 15:36:46At present, solar drying, hot air drying, microwave drying equipment, vacuum drying and vacuum freeze-drying are the main drying technologies of green leafy vegetables. The working principle, technical characteristics and application status of these drying technologies in green leafy vegetables processing are introduced.

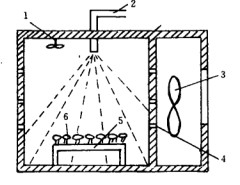

1.1 solar microwave drying equipment

Solar drying is a low-temperature drying technology, using solar energy as the energy source, the dried materials directly absorb solar energy, or through convective heat transfer with the air heated by the solar collector to obtain heat, the surface of the material after the heat is transferred to the material inside, so that the moisture contained in the material from the material inside the liquid. In the form of state or gaseous diffusion, it gradually reaches the material surface, and then diffuses into the air through the gas film on the material surface, so that the moisture content in the material gradually reduces, and finally realizes the drying of the material.

The effects of solar drying and natural drying on the nutritional components of African spinach were compared. The results showed that the spinach dried by solar energy retained more carbohydrates, proteins, minerals and vitamins (P < 0.05), and the microbial load was lower than that dried by natural drying (P < 0.05). This indicates that solar drying is more nutritious and relatively hygienic than natural drying.

The thin layer drying characteristics of coriander leaves in natural convective solar dryer were studied, and the thermodynamic behavior of solar drying was evaluated. It was found that with the increase of solar radiation, the air temperature at the entrance of the dryer increased, the moisture content of the wet base of the coriander leaves decreased from 88% to 4.5% and the Midilli-Kucuk model was the best one to describe the drying law, and the energy efficiency was 7.81% ~ 37.93% and the efficiency was 55.35% ~ 79.39%.

Compared with natural drying, solar drying is completed in a specific device, which improves the drying temperature, shortens the drying time, avoids the pollution of sand, dust and so on, and has the function of sterilization because of the higher drying temperature; compared with conventional energy drying device, solar drying is energy-saving and environmental protection, transportation. The cost is low. But the solar drying is affected by the climate greatly, the controllability is poor, and the simple solar dryer has small capacity and low thermal efficiency, while the large and medium-sized solar dryer has large investment and large area, which hinders its popularization and application.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply