- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Experimental study on drying letinous edodes with far infrared microwave

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Experimental study on drying letinous edodes with far infrared microwave

2018-11-08 11:45:45

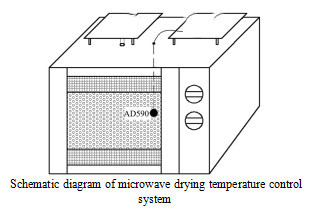

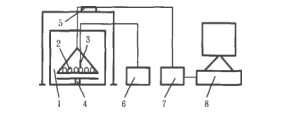

Absrtact: In order to improve the quality of dried Lentinus edodes, the drying experiments of fresh Lentinus edodes were carried out in the far-infrared drying chamber at 60 C and microwave at 0.8 W/g. The results showed that the far-infrared drying and microwave drying equipment had three stages of accelerated drying, constant drying and decelerated drying, but the accelerated drying stage of microwave drying was very short. Quickly enter the constant speed drying section. The fresh letinous edodes was first tested with far-infrared and microwave combined drying.

The results showed that the higher the moisture content, the higher the drying rate and the lower the energy consumption, but the quality of dried mushroom declined after drying. When the moisture content was about 53%, the quality of dried mushroom reached the best. The higher the temperature of far-infrared oven, the higher the drying rate, the lower the energy consumption, but the dried product. When the microwave drying power per unit mass is about 1.13 W/g, the quality of dried Lentinus edodes reaches the best.

Key words: far-infrared; microwave drying letinous edodes; joint drying letinous edodes

Drying is one of the most important means of fresh mushroom processing and storage at present. The contradiction between economy and product quality control of traditional dried mushroom production is increasingly prominent. How to reduce costs and improve product quality is an urgent problem to be studied and solved in the research of dried mushroom.

Experts at home and abroad have done a lot of research on dry food by microwave and far-infrared methods. For example, Liu Yunhong has studied the effects of different ultrasonic power and far-infrared radiation temperature on the drying time, drying rate, diffusion coefficient, microstructure and energy consumption of pumpkin slices.

The process parameters of hot air-vacuum combined drying of Pleurotus eryngii were optimized by three-factor quadratic general rotary combination design; the combined drying method of hot air and microwave was explored to compare the drying technology of agricultural materials; and the combined drying technology of hot air and microwave of okra was optimized by three-factor quadratic rotary regression test. Drying characteristics of kiwifruit slices combined with hot air, microwave and hot air microwave drying were studied.

There are still many studies on material combined drying, but there are few studies on microwave and far-infrared drying of Lentinus edodes, especially far-infrared and microwave combined drying of Lentinus edodes.

Far infrared has a certain penetrability. After drying, the product has good quality, fast drying speed and energy saving. Microwave has very strong penetration and is suitable for agricultural products which are difficult to dehydrate or lose moisture in later drying stage. In this paper, the combined drying of Lentinus edodes by far-infrared radiation in the early drying stage and microwave in the later drying stage was studied, which will provide theoretical basis for optimizing the drying method and technology of Lentinus edodes.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply