- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Pleurotus eryngii vacuum microwave drying process

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Pleurotus eryngii vacuum microwave drying process

2018-11-13 11:24:01

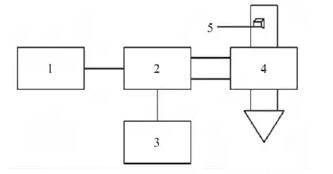

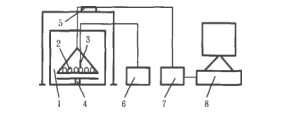

Abstract: The response surface method was used to optimize the vacuum microwave drying equipment of Pleurotus eryngii combined with drying. The effects of various parameters on the puffing rate and sensory quality of dried Pleurotus eryngii were analyzed, and the puffing rate of dried Pleurotus eryngii (y1) was established. Mathematical regression model of sensory score (y2) and initial moisture content code (x1), microwave intensity coded value (x2), and microwave time coded value (x3).

The results show that the regression equation is y1 = 1. 46 - 0. 16x1 + 0. 10x2 + 0. 093x3 - 0. 13x 2 , y = 6. 45 + 1. 22x + 0. 41x + 0. 36x + 1. 01x x + 0. 74x x - 0. 94x 2 - 0. 85x 2 , the best process parameters are 75% initial moisture content of Pleurotus eryngii, microwave strength 20 W / g, microwave time 105 s, the dried products of Pleurotus eryngii obtained under this condition have good color, crispy taste and rich apricot Mushroom flavor.

Key words: Pleurotus eryngii microwave drying; vacuum microwave; drying; process

Pleurotus eryngii (Pleurotus eryngii), also known as Pleurotus eryngii, belongs to the fungus Pleurotus ostreatus. Pleurotus eryngii is rich in flesh, crisp in texture, dense in stipe structure, can be eaten all, and the stipe is more crispy and refreshing than the cap, with pleasant almond flavor and abalone taste, known as "Pleurotus ostreatus" ", suitable for preservation, processing.

Pleurotus eryngii is rich in nutrients, rich in protein, carbohydrates, vitamins and various minerals, and has a high edible value. Pleurotus eryngii is one of 18 edible fungi with three characteristics of “Natural, Nutritional, and Health Care” in line with the standards of the Food and Agriculture Organization of the United Nations (FAO) and the World Health Organization (WHO).

Pleurotus eryngii has a high water content. After standing for a few days at room temperature, the surface of the mushroom body is browned, and the cap membrane is autolyzed. At the same time, the white flocculent mold grows and rots, and the edible value is lost. The off-site transportation and fresh sale of the mushroom. The main method for prolonging the shelf life of mushrooms is to dry. The drying of Pleurotus eryngii is mostly done by sun drying, baking, frying, etc., but there are many problems such as nutrient damage, poor appearance quality, low grade, low processing value and so on. .

In response to the above problems, the author's project team introduced hot air-vacuum microwave-air-expansion combined drying technology to improve the drying quality of Pleurotus eryngii by combining three techniques. In this study, the vacuum microwave drying process in the combined drying of Pleurotus eryngii was optimized. The expansion rate and sensory score of the combined dry final product were used as the index. Based on the single factor test, the response surface was used to determine the initial moisture content and microwave intensity. It is optimized by three factors of microwave time, in order to obtain dry products of Pleurotus eryngii with high expansion rate and good quality, and provide technical support for the industrialization of Pleurotus eryngii combined with drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply