- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Current status of mahogany wood drying process

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Current status of mahogany wood drying process

2018-11-14 16:46:48

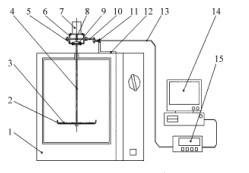

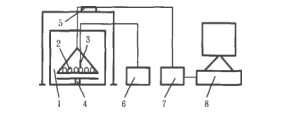

The microwave drying equipment places the wood to be dried in a microwave electromagnetic field. Under the action of the microwave electromagnetic field, the water molecules in the wood are polarized, and the high frequency of the water molecules in the wood is rapidly oscillated by the frequent alternating electromagnetic fields, so that the electromagnetic field The electrical energy is converted into heat between the water molecules, which heats the wood.

Because microwave has superior penetrating ability, independent of the thickness of wood, the intensity of water in wood increases with the increase of moisture content of wood, while the moisture content of wood under natural conditions increases gradually from the inside to the outside. Large, this makes the heat inside the microwave drying wood larger than the outside, which is basically consistent with the gradient of the moisture content of the wood itself, further speeding up the migration of moisture inside the wood to the surface of the wood.

This unique drying mechanism makes microwave drying always known for its fast drying speed, good drying quality, and the ability to maintain the original color of wood. Due to the small stress caused by microwave drying, the dried wood can be used as a semi-finished furniture. dry. However, Yang Pei et al also pointed out the shortcomings of microwave drying, such as: the mutual interference between microwaves during the drying process of wood and the reflection of the inner wall of the equipment, resulting in uneven electromagnetic field density, resulting in uneven heating of wood; The high steam pressure that exists in the interior of the wood will also cause damage to the internal structure of the wood, causing the mechanical strength of the wood to decrease, and the local moisture content will also cause local overheating, resulting in carbonization of the wood.

Microwave drying is currently only in the experimental stage. It is still necessary to carry out systematic authoritative research on various parameters in the microwave drying process, find out the correlation of various parameters, and obtain the optimal drying process parameters, in order to fully utilize the microwave drying characteristics. Better control of dry quality.

The structural characteristics of mahogany wood determine that mahogany is more difficult to dry than other woods. The practicability, artistry and collectability of mahogany furniture place demands on the dry quality of mahogany wood. The current status of the mahogany wood drying industry has also forced the industry to seek self-transformation, so the healthy development of the mahogany drying industry is inseparable from change and innovation.

The author believes that we can seek breakthroughs on the basis of conventional drying advantages. We can also find new development directions in new methods, new technologies and new equipment, integrate industry superior resources, rationally arrange and optimize industrial structure, and find suitable innovative ways. In order to be bigger and stronger, improve the overall level of the industry.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply