- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Drying process of wood white fungus in Tongjiang section

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Drying process of wood white fungus in Tongjiang section

2018-11-30 14:44:53

Abstract : This paper studies a drying process suitable for the wood fungus in Tongjiang section to facilitate its storage and transportation.

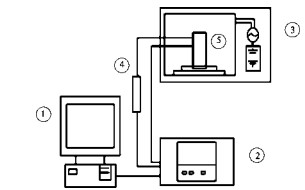

Using 6 different drying methods (hot air constant temperature / variable temperature drying, freeze drying, microwave drying equipment, microwave - hot air combined drying and freezing - hot air combined drying), the wood fungus of Tongjiang section is dried, and the sensory of dried Tremella is analyzed and determined. The scores (out of 10), rehydration ratio, browning degree and energy consumption are used, and the coefficients are weighted by the coefficient of variation method. The highest total score is the best drying method.

The results showed that different drying processes had significant effects on each index (p<0.05), and the degree of influence varied. The highest weighted score was the hot air gradient (35 °C~50 °C, 50 °C~40 °C). The sensory score, rehydration ratio, shrinkage rate, browning degree and unit energy consumption were 8.52, 9.04, 27.87%, 0.313 and 34.56 kJ/g, respectively. Followed by freeze-hot air drying and freeze drying.

It is more efficient to produce high-quality dried white fungus dry by hot air drying and drying. The appearance quality is close to the optimal freeze-hot air drying of the sensory score, but the cost is lower than the latter, and the operation is simple. It is a kind of drying that can be deeply researched and promoted. the way.

Key words: Tremella microwave drying; drying method; hot air gradient drying

Tremella is abundant in the southern provinces of China, with an annual output of hundreds of thousands of tons. Among them, the wood white fungus of Tongjiang section of Sichuan Province, which has been protected by the national origin, is recognized by the Chinese medicine industry as more medicinal value and medicinal effect. People love it.

The moisture content of the fresh Tongyin wood fungus is generally 85%~95%, which is difficult to store, transport and preserve. Therefore, drying is the most important method to solve the storage and transportation of Tremella. At present, the drying techniques commonly used are natural drying, hot air drying, vacuum freeze drying, microwave drying, electromagnetic wave heating drying, and combined drying techniques using two or more drying techniques.

Hot air drying has the advantages of simple operation and low cost, but the dehydration speed is slow and the product quality is poor. Vacuum freeze-drying can maintain the product quality to the utmost, but the energy consumption is high and the operation is complicated; the microwave drying has the advantages of fast and low energy consumption. However, after drying, the quality of the product is poor and the degree of nutrient damage is large.

The traditional white fungus is mostly dried by constant temperature hot air, and there are few reports on the experimental research on the hot air drying of the white fungus. The temperature change drying is more energy-saving, higher quality and more efficient than the constant temperature drying. Currently, it is in mushrooms, carrots, cantaloupe and rice. There are more research reports on agricultural products.

The test uses hot air constant temperature / variable temperature drying, microwave drying, freeze drying, microwave - hot air combined drying and freeze - hot air combined drying six kinds of drying methods, the quality index of the obtained dry products is measured and analyzed, and the best process of Tremella drying is discussed. Conditions, in order to obtain a high quality, low energy consumption and high efficiency drying method to promote the development of the Tremella dry processing industry.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply