- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on the Drying Processing Technology of Cabbage

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on the Drying Processing Technology of Cabbage

2018-12-05 14:11:28

Salvage cabbage, also known as heart-nourishing herb, is used as vegetable food. It can be cooked in boiling water and cooked in cold, stir-fried, soup, juice or processed into salvage cabbage food and beverage.

Save heart cabbage has the functions of nourishing heart, calming liver, lowering blood pressure, lowering blood lipid and preventing or delaying vascular sclerosis. Long-term consumption has better curative effect on heart disease, hypertension, hyperlipidemia, hepatitis, etc. Besides, it also has better curative effect on hemoptysis, hemoptysis, restlessness, insomnia, palpitation and injury caused by falling beats, so Save heart cabbage is one of them. Ideal health vegetable.

But after picking, the color of cabbage tends to brown and the active ingredients will decrease, so the drying storage technology of cabbage is very important. At present, there is little research on the drying technology of cabbage in our country. This topic mainly uses solar energy steam hot air drying and microwave drying equipment plus pre-treatment to explore the best drying technology.

The raw materials used in the experiment were fresh cabbage with intact stems and leaves and no pests and diseases provided by the farm. The cabbage was packed with fresh-keeping film and put in the refrigerator for use.

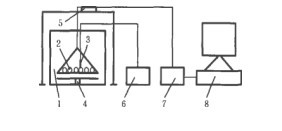

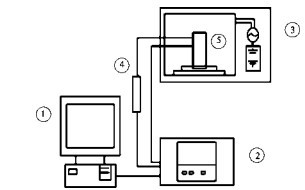

The experimental equipment is a solar steam hot air belt dryer developed by Anhui Agricultural University and a beautiful microwave oven. The testing instruments are solar radiator, infrared thermometer, anemometer and so on.

First, the material is cleaned up cleaned leachate treatment.

Microwave test. The effects of microwave power and time on the drying quality and efficiency of cabbage were analyzed by single factor experiment of microwave drying. The leached materials were weighed into 4 groups, each group consisted of 3 parts, each 500 g. Each material was put into the microwave drying chamber for drying, and microwave power (800W, 640W, 400W, 240W) was set according to the test requirements to dry the materials until they were completely dried. The drying data were recorded and taken from each group. Average.

Pretreatment test. By comparing the pretreatment methods of microwave, blanching and non-blanching, a suitable dewaxing process for cabbage was found. Nine groups of raw materials were weighed, three parts in each group and 500 g in each. They were pretreated by non-blanching, blanching and microwave respectively. Then they were dried by hot air in a belt dryer at 55 C. Data were recorded and their average values were taken.

Hot air drying test. The effects of temperature and wind speed on drying efficiency and quality in hot air drying were analyzed. Weighing four groups of raw materials, each group of three parts, each 500 g, using the dryer temperature control equipment to set the temperature inside the dryer (50, 55, 60, 65 C), dryer internal wind speed setting (0.3m/s, 0.8m/s, 1.2m/s, 1.8m/s) Then the material is dried by hot air. The weight of the dried material is measured every 0.5 h, and the data are recorded and the average value is taken.

1) The microwave drying experiment of cabbage was carried out, and the effects of microwave power on drying characteristics of cabbage and the effects of hot air temperature and speed on drying characteristics of cabbage were obtained.

2) The microwave pretreatment is the best method through the pretreatment control experiment.

3) Through quadratic general rotary regression orthogonal experiment, the model equation of drying time and sensory quality score of products was established.

4) By optimizing the regression equation, the optimum technological parameters of Microwave-hot air combined drying of cabbage were obtained. The optimum technological parameters of cabbage drying are as follows: material layer thickness 0.5 cm; microwave drying, microwave power 640 W, microwave time 4.2 min; then hot air drying, hot air temperature.

The drying time is about 272 minutes at 55 C, 1.5 m/s of wind speed.

5) Contrast experiments of Microwave-hot air combined drying with hot air drying after blanching and hot air drying without blanching were carried out to verify that the quality of cabbage obtained by Microwave-hot air combined drying was the best.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply