- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of apple microwave drying scheme based on electronic nose odor detection

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of apple microwave drying scheme based on electronic nose odor detection

2018-10-31 17:25:16

Abstract: In microwave drying, improper setting of process parameters will cause material structure damage and surface burnt, which is often accompanied by the emission of characteristic odor. This article takes apple as the object, adopts 60, 70, 80 °C constant temperature, fuzzy logic control and linear temperature control 5 kinds of drying schemes, through the odor map collected by electronic nose, studies the emission law of characteristic odor, and optimizes the drying scheme. According to the variation rule of apple flavor peak and coke paste peak in the odor map of the constant temperature scheme, the fuzzy logic control scheme determined can realize the on-line adjustment of the magnetron power, preserve the flavor and reduce the burntness. Optimize the measured material temperature curve in the fuzzy logic control scheme, determine the linear temperature control scheme, and eliminate the electronic nose detection link, which is more suitable for industrial applications.

By comparing the product quality of different microwave drying equipment, the quality of the dried product under the linear temperature control scheme is high, time-consuming and strong, and the drying ability is a priority. This study provides a technical basis for the application of odor detection technology to apple drying.

Key words: apple microwave drying; temperature; odor detection; control scheme; apple

Introduction

Apple is widely loved by consumers since the early 1920s.

More than 300 volatile aromatic substances have been isolated from the odor of apples. Only a small part (about 20-40 kinds) of volatile components have been determined to have a decisive influence on sensory quality. In recent years, there has been a lot of research on the smell of apples, but many studies have focused on the classification and storage of apples. Only a part of the research is related to the drying process or parameter control. Three representative volatile components of apple during hot air drying and freeze drying were analyzed by gas chromatography-mass spectrometer (GC-MS).

The loss of volatile components of top red apples under different drying conditions was determined by infrared (IR) moisture analyzer. The quality of apple slices with different drying methods including odor characteristics was analyzed and compared by GC-MS. The above analysis is limited to the offline or quality detection of volatile components of apples. At present, there are few studies on the on-line detection and control of apple odor during the drying process.

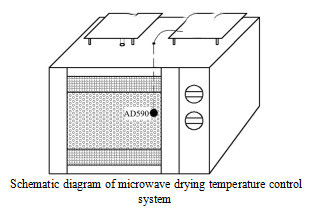

In this study, a microwave drying system based on online odor detection was designed. The parameters of the drying process were adjusted according to the odor map collected in real time, and the apple was used as the object for experimental research. Finally, the advantages and disadvantages of different drying methods were evaluated by indicators such as volatile component detection, time consumption, drying ability and sensory evaluation. The specific objectives of this study are as follows: online detection of the odor profile of apple samples during microwave drying; two improved schemes of fuzzy logic control and linear temperature control were proposed; the drying capacity and sample product quality of the system under different microwave drying schemes were compared.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply