- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research status of traditional rapeseed drying technology

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research status of traditional rapeseed drying technology

2018-11-06 15:05:07

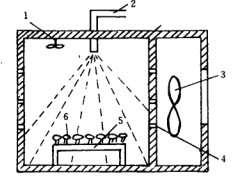

Microwave drying is a method that uses microwave as drying medium to heat materials to promote water evaporation and remove water from materials. As a traditional drying method, microwave drying equipment has been quite mature. In agricultural production, microwave drying has been widely used in foreign countries, but due to the high energy consumption and high cost of drying process, some domestic grain and oil processing enterprises have used it.

In the drying process of rapeseed, because of the thin cotyledons in the cortex, it is necessary to cool the rapeseed after drying in order to prevent moisture absorption and moisture regain of rapeseed. The hot air drying technology of commonly used rapeseed is: preheating, heating, drying, precipitation, cooling and cooling. In order to ensure drying speed and drying quality, the drying temperature of rapeseed is generally not higher than 75. In addition, rapeseed particles are small, and the pressure drop of hot air passing through rapeseed voids is large, so the drying wind speed should not be too fast, and the wind speed below 2 m/s is more appropriate. In the research of hot air drying technology of rapeseed, there are many and complete studies on the mechanism, technology and quality of hot air drying of rapeseed abroad, but the domestic theoretical research is relatively insufficient.

As a necessary treatment link after rapeseed harvest, drying has the problem of high oil content in rapeseed, and unreasonable drying process can easily make the quality of rapeseed decline in the drying process. Domestic and foreign research on hot air drying rapeseed quality is more comprehensive, basically covering the main rapeseed and rapeseed oil evaluation indicators. Kanai et al. studied the effects of drying conditions on rapeseed and sunflower seeds. Especially, the quality of rapeseed oil was evaluated by color, peroxide value and acid value. It was found that the quality of rapeseed oil obtained in advance was relatively poor, and it was green because of residual chlorophyll. Rapeseed and rapeseed should be dried at lower temperature as soon as possible after harvesting. Dry, to ensure that the rapeseed will not deteriorate and the quality of oil.

Gawrysiak-Witulska et al. studied the effects of natural air drying and post-drying storage on tocopherols and 8-nicotinate tocopherols in rapeseed. It was found that drying could reduce tocopherols by 6%-11% and further decrease by 23%-30% during subsequent storage. The amount of variation is similar to that of tocopherol.

Sutherland et al. analyzed the changes of peroxide value and free fatty acid content of rapeseed and sunflower seeds dried by hot air, and concluded that the germination rate was affected by the temperature of air and rapeseed. For sunflower seeds, rapeseed with different initial moisture has different safe drying temperatures, while rapeseed germination rate does not decrease at 60 C, and heat treatment has no significant effect on free fatty acid content. Thakor et al. analyzed the size and quality of individual rapeseed particles in the drying process by thermogravimetric analysis. It was concluded that the higher the moisture content of rapeseed seeds, the larger the shrinkage of rapeseed particles; the higher the moisture content of intact seeds, the higher the water diffusion rate; and the particle radius in the first-order drying kinetics equation. The dynamic value is more accurate than the fixed value.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply