- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying processes on quality and volatile flavor components of Pleurotus abalone

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying processes on quality and volatile flavor components of Pleurotus abalone

2018-11-07 14:28:21

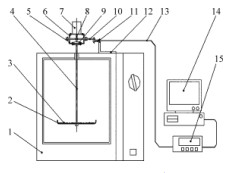

ABSTRACT: In order to study the effects of different drying methods on the quality and volatile flavor of Pleurotus eryngii, the drying mode of Pleurotus eryngii was optimized. Four drying processes, heat pump, hot air, vacuum freezing and vacuum microwave, were used to dry fresh Pleurotus eryngii. The main nutrients, colority and sugar of Pleurotus eryngii were analyzed with different microwave drying equipment. (sugar alcohol) and volatile flavor components.

The results showed that the total protein content of Pleurotus eryngii was less affected by drying method, the total sugar content was the lowest (13.56%) under vacuum microwave drying, the total phenol content (39.97 ug/g) and crude fat content (1.27%) were the lowest under vacuum freeze-drying, and the color of Pleurotus eryngii was better maintained by vacuum freeze-drying.

The trehalose content in Pleurotus eryngii was affected by drying methods as follows: heat pump > vacuum freezing > hot air > vacuum microwave drying. The main changes of mannitol content were heat pump and vacuum freezing > hot air and vacuum microwave. 68 volatile flavor components were identified under four drying methods of Pleurotus eryngii. The relative content of aldehydes was the highest after heat pump, hot air and vacuum microwave drying. The main flavor components were isovaleraldehyde, n-hexanal and 2-methylbutyraldehyde. The relative content of alcohols was the highest after vacuum freeze-drying, mainly 1-octenetriol. Esters, ketones, hydrocarbons, pyrazines and a small amount of other substances were also detected, and the flavor components interacted to form different flavors. Compared with different drying methods, vacuum freeze-drying can better maintain the quality and flavor of Pleurotus eryngii, heat pump drying can achieve a better balance in terms of economy and stability.

Keywords: microwave drying of Pleurotus abalone; quality; volatile flavor.

Dry as a kind of important processing unit has been widely used in the modern food industry, it can reduce the moisture content, inhibit microbial growth and internal material with water as the reaction medium of occurrence, so as to prolong the shelf life and reduce the freight cost. For food drying are the main methods of heat pump drying, hot-air drying, vacuum drying, vacuum microwave drying, there are different effects of different drying methods of main nutritional components of material, color, flavor etc..

Fresh mushroom is fresh because of the respiration intensity and high water content, dry edible fungus is currently commonly used preservation methods. But in the drying process, the problems of edible nutritional change bacteria and flavor loss, drying methods and different effects on the nutrition and flavor are also different, which directly affect the quality of products.

The volatile flavor of edible fungi is important factors of quality and public acceptance, studies show that the flavor components of bacteria in food including volatile aldehydes and ketones, esters and sulfur compounds, different processing methods have flavor components which contain the difference. Solid phase microextraction and gas chromatography mass spectrometry (gas chromatography-mass spectrometer, GC-MS) spectrometer has been widely used in the analysis of volatile and semi volatile flavor components of aroma in the drying process of the formation mechanism is also very effective. Research shows that the gradual warming of the dry mushroom browning less, good quality; Tang Huimin research the influence of several kinds of drying methods on the quality of Momordica charantia powder, freeze-drying bitter keep good color, low moisture content, vacuum drying and air time.

This study used fresh mushroom heat pump drying and hot air drying, vacuum freeze drying and vacuum microwave drying process, the change of main nutrients, GC-MS was used to analyze the effect of different drying methods on volatile flavor components of Pleurotus eryngii, explore the aroma formation mechanism on the development and utilization of resources with mushroom Have a certain reference value, and provide theoretical and practical basis for the development of appropriate drying of mushroom products.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply