- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying of carrot slices by pulsed electric field pretreatment

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying of carrot slices by pulsed electric field pretreatment

2018-11-07 15:17:46

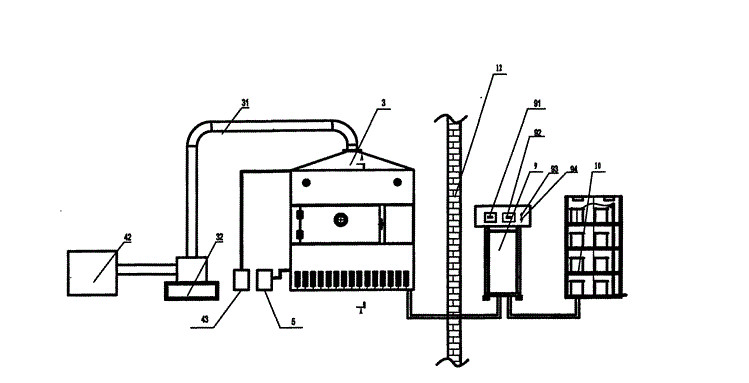

ABSTRACT: In order to investigate the effect of pulsed electric field pretreatment on microwave drying equipment of carrot slices, quadratic regression orthogonal combination experiment of four factors (pulse frequency, electric field intensity, microwave power density and slice thickness) was designed with the precipitation rate and rehydration rate per unit time of microwave drying of carrot slices as experimental indexes. The drying rate curve of carrot slices after microwave drying was processed.

The microwave drying kinetics equation and regression equation of each index of carrot slices after pretreatment were obtained by regression analysis with SPSS software, and the indexes were optimized synthetically.

The results showed that the dynamic equation of microwave drying of carrot slices pretreated by pulsed electric field was piecewise applicable to Page model; the effect of pulse frequency and electric field intensity on the precipitation rate per unit time of microwave drying of carrot slices was significant; the effect of pulse frequency on the rehydration rate was significant; the effect of electric field intensity on the rehydration rate was not significant; and the optimal process combination was not significant. The pulse frequency is 30 Hz, the electric field intensity is 2.0 kV/cm, the microwave power density is 1.0 W/g and the slice thickness is 4.0 mm. Under the optimum technological conditions, the precipitation rate per unit time and rehydration rate of carrot slices are improved.

Key words: agricultural products, drying, microwave devices, pulsed electric fields, carrot slices microwave drying

Quote

Pretreatment methods for fruit and vegetable drying include osmotic dehydration, radiation, freezing or vacuum freezing, pulse electric field (PEF) pretreatment, etc. These drying pretreatment methods can improve product quality and/or reduce subsequent drying energy consumption, and have practical application value. Among them,

PEF technology is a new technology applied in fruit and vegetable drying pretreatment. It has the advantages of short processing time, low cost and little impact on the quality of materials. It has attracted the attention of scholars and professionals at home and abroad.

In recent years, the application of PEF technology in drying and dehydration pretreatment of fruits and vegetables has been developing rapidly. The effects of PEF pretreatment on the drying characteristics of bell pepper and apple slices were studied. It was pointed out that PEF pretreatment could improve the porosity of materials, accelerate the rate of water loss in convective drying, and increase the rehydration rate of apple slices by 10%-30%.

M. I. Bazhal et al. found that PEF pretreatment not only affected the cell membrane, but also the integrity of the cell wall. After hot air drying, the porosity of apple slices pretreated with PEF increased by 5% and the shrinkage decreased by 30%.

N.I. Lebovka et al. published the paper that PEF pretreatment can improve the convective drying rate of potato chips. It was found that the effective diffusion coefficient of potato increased with the increase of cell damage caused by PEF pretreatment. E. Amani et al. studied the effect of PEF pretreatment combined with osmotic dehydration pretreatment on convective drying of carrot slices. In China, the effects of PEF pretreatment on the characteristics of hot air convective drying of sweet potato and apple slices were studied respectively.

From the above, most of the studies are about the effects of PEF pretreatment or combined with osmotic dehydration pretreatment on hot air convective drying characteristics of fruits and vegetables. According to the current literature search, there are few reports about the effect of PEF pretreatment on microwave drying characteristics of fruits and vegetables. The purpose of this study was to explore the effect of PEF pretreatment on microwave drying characteristics of carrot slices, establish the microwave drying kinetics equation and regression equation of each index of carrot slices pretreated with PEF, and optimize the index synthetically, find out the optimal combination of technology, and provide valuable reference for future research.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply