- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying method on the quality of instant rice

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying method on the quality of instant rice

2018-11-08 13:20:50

Abstract: The effects of hot air drying, microwave drying equipment, microwave heating air drying, hot air and microwave drying on the quality of instant rice have been studied. The results show that the quality of instant rice produced by the combination of microwave and hot air is better than that of rice. Other methods. The raw materials were pretreated, microwaved (690W) for 9 minutes, and then dried at 80 °C for 40 minutes, and the prepared convenient rice had good rehydration performance. After rehydration, the rice is rich, the taste and flavor are similar to fresh rice, and the rehydration rate can reach 2,47.

Key words: convenient rice microwave drying; hot air drying

Rice is one of the staple foods that our people love, but it takes a long time to cook and is inconvenient to eat. It is difficult to adapt to the needs of modern society. To this end, China Food Industry Association decided to develop and produce convenient rice products as one of the key industry priorities in 1995. Drying is the key to convenient rice production. The existing convenient rice drying methods mainly include hot air drying, vacuum drying and freeze drying.

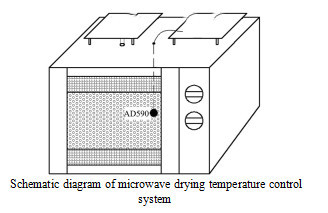

These methods have a long drying time and high energy consumption. Microwave drying has been used in a variety of food production, but has not been studied in the drying of convenient rice. In this paper, the effects of hot air drying, microwave drying, hot air plus microwave drying and microwave heating and air drying on the quality of instant rice were studied.

in conclusion

The drying method has a significant effect on the quality of the convenient rice. The hot air-dried instant rice has good color, and the suitable hot air drying condition is temperature 80C, 100min. Microwave drying is convenient for rehydration of rice. The final water content of the product is low and the drying time is short. The suitable conditions are microwave energy 460W and drying for 26 minutes.

The microwave-dried hot air-dried instant rice has the best comprehensive quality, and the rehydration rate can reach 2.47. The sensory indexes are good. The suitable conditions are firstly dried with 690W microwave for 9min, then dried by 80°C hot air for 40min. The drying time is about 49% of hot air drying (80C). The combination of microwave and hot air drying has a greater overall quality than that of microwave or hot air drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply