- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying characteristics and temperature and moisture change simulation of flake food

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying characteristics and temperature and moisture change simulation of flake food

2018-11-10 10:06:31

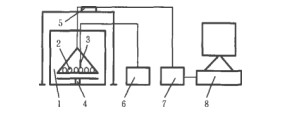

Abstract: In order to grasp the microwave drying law of sheet-like food materials and provide reference for production application, potato was selected as experimental material, and it was carried out under different microwave energy levels (2.2~3.6 W/g) and slice thickness (2-6 mm). Microwave drying experiments were carried out to determine changes in material temperature and moisture content during microwave drying.

Based on the heat balance equation and the diffusion equation, the corresponding model is established and solved by the finite difference method. The experimental results are basically consistent with the model calculation results.

The microwave drying equipment of sheet material undergoes three stages of preheating, constant temperature and rapid temperature rise: the material dehydration is less in the preheating stage; the material loses most of the water in the constant temperature stage, and the temperature increases as the slice thickness and the microwave power/mass ratio increase. In the rapid heating phase, the material drying rate decreases and its temperature rises rapidly. The drying rate is not affected by the change in the thickness of the material slice, but increases as the microwave power/mass ratio increases.

Key words: simulation; microwave drying flake food

Different from the traditional hot air drying method, the microwave has strong penetrating power and generates an internal heat source in the wet material. After the microwave energy is absorbed, the material directly heats up and rapidly dries. The mechanism of heat and mass transfer during microwave drying is very complicated. The analysis of the heat and mass transfer mechanism in the microwave heating and drying process and the establishment of the basic theoretical model of microwave drying will help to grasp the changing rules of the drying process and optimize the drying process.

In the drying of food materials, flake wet materials are a kind of widely used drying objects. Most of their research on microwave drying focuses on the effects of microwave power, material shape, size, material parameters and exothermic humidity conditions on the drying rate of materials. The research on the temperature change of the material during microwave drying and its influencing factors are less involved, and the microwave drying characteristics are still unclear.

To this end, for the flake wet food materials, microwave heating was used for drying experiments, the microwave drying characteristics of the flake food materials were investigated, and a mathematical model for changing the temperature and moisture content of the materials during the microwave drying process was established to grasp the microwave of the flake food materials. Provide reference for drying rules and production applications.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply