- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of hot air temperature on drying characteristics and physical and chemical quality of bitter gourd slices

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of hot air temperature on drying characteristics and physical and chemical quality of bitter gourd slices

2018-11-12 10:32:36

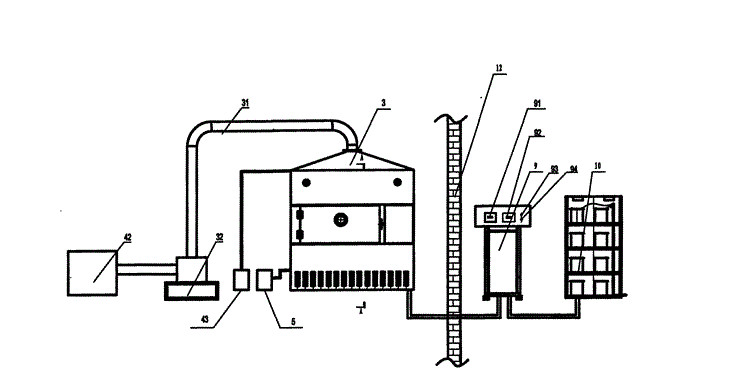

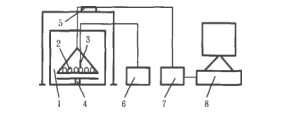

Abstract: Using fresh bitter gourd as raw material, the characteristics of microwave drying equipment and physical and chemical quality were studied after hot air drying at 40, 50 and 60 °C.

The results showed that the hot air temperature significantly affected the drying characteristics of bitter gourd slices. The higher the hot air temperature, the higher the drying rate of bitter gourd slices, the shorter the drying time, the higher the effective diffusion coefficient of water. The activation energy of bitter melon tablets after hot air drying at 40~60 °C was 14.40 kJ/mol; Among them, the hot air drying treatment time of 60 °C is short, and the dried bitter gourd tablets have large rehydration ratio, low browning degree, high total phenol and total flavonoid content, and strong DPPH·clearing ability. Therefore, 60 °C is the optimum temperature for hot air drying of bitter gourd slices.

Key words: bitter gourd microwave drying; hot air temperature; drying characteristics; quality

Momordica charantia L. is a genus of cucurbitaceae that is widely distributed in tropical, subtropical and temperate regions. Bitter gourd is rich in bitter melon, protein-like active substances, amino acids, cellulose and multivitamins, as well as various minerals such as K, Na, Ca, Mg, P, Fe, etc., which have the functions of clearing away heat, nourishing blood, nourishing Qi and nourishing the liver. It is a typical medicine and food plant for the purpose of tonifying kidney and strengthening spleen and improving immunity.

Fresh bitter gourd has a water content of over 90%, is highly perishable and is not resistant to refrigeration, and has a short shelf life. Drying is the main preservation and processing method of bitter gourd fresh products, which is conducive to the preservation and deep processing of raw materials. At present, the drying methods of bitter gourd are mostly hot air drying, microwave drying, freeze drying, heat pump drying, spray drying, gas jet impact drying, combined drying, etc., and research focuses on drying characteristics and kinetics, drying process optimization, and drying quality.

Compared with other drying methods, hot air drying has the characteristics of simplicity, convenience, high efficiency and low cost, and has great application potential in bitter melon drying. By exploring the effects of hot air temperature on the drying characteristics and physical and chemical properties of bitter gourd slices, the optimum temperature for hot air drying of bitter gourd slices was determined, which provided a theoretical basis for hot air drying of bitter gourd.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply