- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Experimental study on drying characteristics and quality of jujube tablets under different drying methods

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Experimental study on drying characteristics and quality of jujube tablets under different drying methods

2018-11-12 11:19:21

Abstract: In order to study the effects of different drying methods on the drying characteristics and quality of jujube tablets, semi-dry jujube was used as experimental material. After slicing, solar shaving, vacuum freeze drying and microwave drying equipment experiments were carried out on different thickness jujube tablets. The sensory evaluation and nutrient composition analysis of the dried jujube tablets were carried out.

The comprehensive sensory evaluation and drying characteristics analysis showed that the best experimental conditions for solar drying were solar wall collector type device, the thickness of jujube piece was 4 mm; the best experimental condition for vacuum freeze drying was shelf temperature 40 °C, jujube piece The thickness is 6 mm; the optimal drying conditions for microwave drying are microwave power 70 W and jujube thickness 6 mm. The results of nutrient test showed that the Vc content and total sugar content of the jujube tablets obtained by vacuum freeze-drying were the highest. The results of the study can provide guidance for the actual drying of the jujube tablets.

Key words: jujube tablets microwave drying; jujube; drying characteristics; nutrients

As one of the most unique and advantageous fruits in China, jujube is deeply loved for its rich nutrients. With the rapid development of agricultural planting technology, the yield of jujube has increased year by year. Due to the oversupply of the market, the semi-dry dates are hoarding. Therefore, the development of new varieties of jujube products has become an urgent need. In recent years, crisp jujube, jujube tablets, jujube powder and other products have been listed. Among them, crisp jujube and jujube tablets are mostly made by frying. Although the taste is crispy, the oil content is large, which has adverse effects on health. Therefore, research A semi-dry jujube drying method with high nutritional value and good taste is necessary.

In recent years, scholars have studied the drying characteristics of jujube products (whole jujube, slice, jujube powder) and the effect of drying methods on their quality, but fresh jujube is used as experimental material. Shen Jing et al. compared the comprehensive nutrient composition and sensory evaluation of the four drying methods, and concluded that the best drying method for making jujube slices with fresh winter jujube is microwave vacuum freezing and microwave vacuum puffing; Luo et al. The influence of texture, nutrition and sensory quality (color and aroma) is considered to be complementary to the composite drying technology, ie intermittent vacuum microwave drying. Chen et al. used the response surface method to optimize the process conditions for the production of jujube powder by spray drying method, so that the moisture content, hygroscopicity, brightness and Vc content of the prepared jujube powder were the best quality.

Fang et al. studied the effect of power on the shrinkage rate, density, Vc and browning degree of jujube tablets when microwave dried jujube tablets. The results showed that the Vc content, density and browning degree of jujube tablets obtained by high microwave power drying were lower than that of low microwave power. The dried jujube tablets have increased to varying degrees, while the soluble solids content is reduced. Lee et al. used vacuum drying to study the water diffusion coefficient and dry activation energy of jujube tablets under different temperature conditions. Gao et al. studied the changes of organic acid, phenolic compounds, sugar, VE and β-carotene in jujube tablets before and after oven drying, microwave drying, freeze drying and natural air drying. However, there have been no reports of scholars studying the drying of semi-dried jujube slices.

There are many varieties of jujubes in China, which can reach more than 260 species, among which Xinjiang jujube is large, Vc and total sugar content.

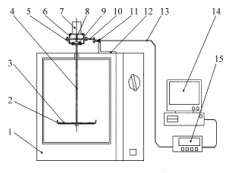

High, deeply loved by consumers. Therefore, in this study, Xinjiang semi-dry jujube was used as experimental material, and solar drying, vacuum freeze drying and microwave drying were used to conduct drying experiments on jujube tablets of different thickness under different drying conditions, and the drying characteristics of jujube tablets were obtained. The sensory evaluation and nutritional value were compared to provide a theoretical basis for the industrial drying of semi-dry dates.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply