- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Hot Air Combined Drying Technology of Low Sugar Chestnut Fruit

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Hot Air Combined Drying Technology of Low Sugar Chestnut Fruit

2018-11-13 11:50:58

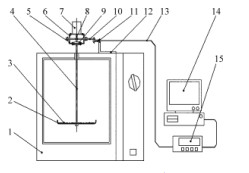

Abstract: The microwave and hot air drying were used to study the quality changes of low sugar chestnut fruit in the drying process. The microwave and hot air drying process of low sugar chestnut fruit was simulated by mathematical modeling. The experimental results show that the optimal drying process is as follows: The initial microwave drying equipment has a power density of 2W/g, the moisture content is dried to 20% (drying time is 18min), and then replaced with 60°C hot air drying to a moisture content of 15%. It always takes 138 minutes.

The low-sugar chestnut fruit can be used for microwave drying in the early stage. The equation can be described by the Henderson and Pabis model. Compared with traditional hot air drying, microwave-hot air combined with dry low-sugar chestnut fruit not only shortens the drying time, but also improves the quality of the fruit.

Key words: chestnut microwave drying, microwave-hot air drying, model

Low-sugar chestnut fruit is dried to reduce the moisture content of the fruit to improve the taste and preservation of the fruit. Because the structure of the chestnut is relatively dense, relatively speaking, the hot air is dried slowly and the drying time is long. The microwave heating speed is fast, which can greatly shorten the drying time and improve the product quality.

The drying kinetics of chestnut showed that the microwave drying rate of chestnut decreased rapidly after the initial increase in drying, mainly in the slow-down drying stage, while the chestnut hot-air drying had obvious constant-speed drying stage, and the overall rate was lower than microwave drying.

However, microwave drying also has shortcomings. When the water content of low-sugar chestnut glutinous rice is low, the microwave drying process will be accompanied by other phenomena affecting product quality such as puffing and local coking, and it is not possible to use only microwave drying in the whole process.

Many scholars at home and abroad have carried out research on microwave and hot air combined drying materials, and achieved good results. The physical properties of low-sugar chestnut fruit can also be combined with microwave hot air drying, and the study by Funebo et al. The treatment can improve the rate of hot air drying. Therefore, from the drying kinetics and drying model of chestnut, the optimum process of combined microwave and hot air drying is determined according to the quality change of low sugar chestnut fruit in the experiment, and then the joint drying equation is obtained.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply