- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of Different Drying Methods on Sensory Quality of Weibei Green Tea

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of Different Drying Methods on Sensory Quality of Weibei Green Tea

2018-11-17 09:12:02Abstract: The effects of drying process on the sensory quality of the green tea of Weibei were discussed in different drying methods. The results showed that the fresh leaves of the northern green tea were the highest in sensory quality after traditional manual frying and drying, followed by the samples processed by blast drying and microwave drying equipment. The samples obtained by vacuum freeze-drying had the lowest sensory quality.

In addition, comparing the different conditions of the same drying method, the sensory quality of the sample treated by microwave drying method under different power conditions is almost the same, and the samples prepared by the blast drying method have higher sensory quality at 100 ° C than 80 ° C.

Key words: Weibei seed green tea microwave drying;drying method;sensory quality

“Qibei Tea” is an excellent tea tree variety in Japan, accounting for more than 3/4 of the domestic tea planting area. It is characterized by good growth, high yield, excellent quality and strong disease resistance. Currently, it is located in Henan, Zhejiang and other places in China. There are plants.

The processing method of green tea mainly includes “killing→drying”, and drying as the last step of green tea processing has a great influence on the quality of tea. Reasonable drying technology can not only remove the moisture in the tea, but also facilitate the storage and improve the quality of the tea. It has been found that during the drying process, some insoluble substances in the tea are cracked and isomerized, which has a good effect on improving the taste of the alcohol and developing the pure aroma.

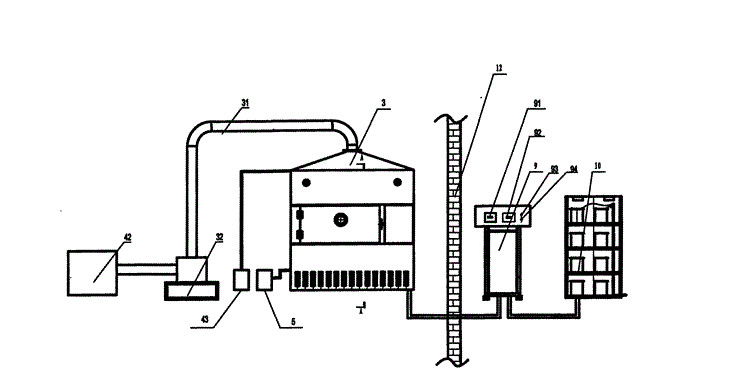

Drying and drying are the drying methods commonly used in green tea processing. In recent years, with the rapid development of science and technology, technologies such as microwave drying, vacuum freeze drying and far infrared drying have been successively applied to tea production. The water loss principle and water loss mode of different drying methods are different, and the corresponding drying process and equipment are also different. Therefore, different drying methods will have a significant impact on the tea flavor, which is the effect on the sensory quality of the tea.

The project mainly uses different drying methods, including manual drying, microwave drying, vacuum freeze drying and air drying, to dry the green tea in the north of the country, and evaluate the different drying methods for the northern Fujian species through sensory quality evaluation. The sensory quality of green tea has some references for the production and optimization of this kind of tea.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply