- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on microwave drying characteristics of rice flour

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on microwave drying characteristics of rice flour

2018-11-19 14:46:29

[Abstract] The characteristics of microwave drying equipment for three common commercially available wet rice noodles were studied. The results show that the water content of rice flour is related to microwave power and drying time. The higher the power, the longer the drying time and the lower the water content. The drying rate of rice flour is proportional to the microwave power. Drying with medium fire can be done in a short time. Get better quality rice noodles.

[Key words] rice flour microwave drying; quality

Rice flour is one of the traditional staple foods in southern China. It has a long history of production, its texture is flexible, smooth and delicious, and is very popular among consumers. The rice flour is produced in a processing process such as milling, pre-steaming, extrusion, molding, re-steaming, dicing, and drying. The water content of the finished dry vermicelli is usually controlled at 11.0%~13.5%, so that the rice flour can obtain better toughness, avoid breakage during storage and transportation, and ensure that the rice noodles do not deteriorate during the shelf life. Therefore, drying is a key part of rice flour processing.

The traditional drying of rice flour is mainly natural drying and hot air drying. Natural drying is easily restricted by external natural conditions, which is not convenient for mechanized production; hot air drying is economical and has a large output. It is widely used in rice flour processing industry, but its drying time is long, energy consumption is high, and products are easily broken to varying degrees. Strips, lack of toughness, paste soup and other shortcomings.

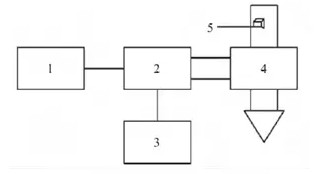

Due to its unique heating characteristics, microwave drying has the advantages of fast drying speed, high energy efficiency and good dry quality. It can not only reduce production costs, improve product competitiveness, but also reduce greenhouse gas emissions and increase environmental affinity. It can solve the problems in the drying process of rice flour well. At present, there are not many researches on microwave drying technology of rice flour. Therefore, the microwave drying test of rice flour is carried out to analyze the microwave drying characteristics of rice flour and its influence on the quality of rice flour, which provides a reference for the industrial application of rice flour microwave drying.

(1) Microwave drying characteristics of three common commercially available wet rice noodles, drying process water content / % broken rate / % hardness / g viscosity / g · s-1 were studied, and the water content and microwave power of rice flour were found. The drying time is related. The higher the power, the longer the drying time and the lower the water content. During the entire drying process, the moisture content of the rice flour decreases approximately uniformly.

(2) The drying rate of rice flour is proportional to the microwave power. Under low power, the microwave drying process of rice flour can be divided into three stages: acceleration phase, constant-speed drying phase and slow-drying drying phase. Under high power, microwave drying of rice flour The process can only observe two phases of the acceleration phase and the

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply