- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of Different Drying Methods on the Quality and Antioxidant Properties of Pickled Cabbage

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of Different Drying Methods on the Quality and Antioxidant Properties of Pickled Cabbage

2018-11-21 09:45:11

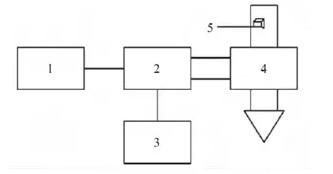

Abstract: The physical, nutrient and antioxidant properties of pickled cabbage powder were studied under freeze drying, spray drying, vacuum drying, microwave drying equipment, hot air drying and extrusion.

The results showed that the content of lactic acid and free amino acid in freeze-dried sauerkraut powder was the highest, which was 48.39% higher than that of hot air drying, 45.45%. The content of soluble dietary fiber in pickled cabbage powder was the highest after extrusion and puffing, which was 64.21 higher than hot air drying. The sprayed and dried pickled cabbage powder has the best brewing property, which is 32.39% higher than that of hot air drying. The quick-drying and vacuum freeze-drying of pickled cabbage powder has better fluidity, and the angle of repose is 25.51% smaller than that of hot air drying. , 23.14%.

Vacuum freeze-drying has the smallest bulk density, which is 31.17% lower than hot air drying. The freeze-drying powder has the lowest bulk density and 42.31% lower than hot air drying. The freeze-drying hydration ability is the highest, and the squeezed and processed pickled cabbage powder has the highest oil absorption capacity. , respectively, higher than hot air drying 61.61%, 77.14%; freeze-drying has the least impact on the hydroxyl radical scavenging rate or lipid peroxide inhibition rate.

Key words: sauerkraut microwave drying; dry method; quality; oxidation resistance

Sauerkraut, known as oyster, is a vegetable product that has been fermented by cabbage (or green vegetables). It has a long history of use in China. It not only preserves the nutrients in the original vegetables, but also is rich in vitamin C and amino acids. The organic acid, dietary fiber and other ingredients, and the lactic acid produced by fermentation also imparts a unique flavor to the sauerkraut and has the effect of maintaining the normal physiological function of the gastrointestinal tract.

In recent years, dry milling has become a trend in the processing and storage of fruits and vegetables, and it has a wide range of applications. First of all, milling can not only increase the added value of the product but also reduce the transportation cost. Moreover, the pickled cabbage powder does not have strict requirements on the size and shape of the raw materials, does not cause residue to cause environmental pollution, and can fully utilize the food in the raw materials. Fiber and nutrients, to achieve full utilization of raw materials, is a viable comprehensive utilization technology.

In this experiment, several different drying methods were used to dry the sauerkraut. After pulverization, the physical properties, nutrient components and antioxidant properties of the sauerkraut powder prepared by different drying methods were compared and analyzed, in order to provide reference for the processing of sauerkraut powder.

The experimental results show that different drying methods have an effect on the nutritional, physical and antioxidant capacities of sauerkraut. Nutritional characteristics of sauerkraut: The content of soluble dietary fiber was the highest in the sauerkraut powder, and the free amino acid content and lactic acid content were the highest in freeze-drying treatment. The physical characteristics of sauerkraut: the quick-drying of pickled sauerkraut powder, spray drying and vacuum The sauerkraut powder obtained by freeze-drying has better fluidity, the minimum bulk density of vacuum freeze-drying, the lowest bulk density, the highest water and capacity, and the highest oil absorption capacity of squeezed and processed sauerkraut; the antioxidant properties of sauerkraut: freeze-drying Both the base clearance rate and the lipid peroxide inhibition rate have the least effect.

On the whole, among the several drying methods, freeze-drying, spray drying and extrusion can well maintain the nutritional, physical and antioxidant properties of the pickled cabbage. Microwave vacuum drying can quickly dry the material under suitable temperature conditions, which can better maintain the nutrient content of the material. The physical properties and antioxidant properties of the processed pickled cabbage powder are better, which is an ideal and more ideal. Practical and popular drying methods.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply