- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying method on physical and chemical properties of galangal

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying method on physical and chemical properties of galangal

2018-11-21 10:43:20

Summary:

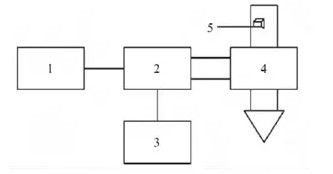

Objective: To investigate the changes of physical and chemical properties of galangal tablets before and after microwave drying equipment, and to determine the best quality and dryness. Methods: Colorimetry, UV spectrophotometer, high performance liquid chromatography, solid phase microextraction-gas chromatography-mass spectrometry were used to investigate the color, total phenolic content, total flavonoid content, galangal of six kinds of drying methods. The effect of the content of the element and the volatile component.

RESULTS: Freeze-drying had the largest comprehensive retention of total phenols, total flavonoids and galangin, total phenol (20.95±0.13) mg/g, total flavonoids (12.19±0.01) mg/g, galangin (11.45±0.03). ) mg/g, followed by vacuum heating and drying, hot air drying, microwave drying, sun drying, and natural air drying; the peak area of volatile substances after natural air drying and sun drying is lower, and the difference in peak area statistics of the other four drying methods is higher. Small; after microwave drying, the color is the deepest, the red and green value a* is 13.92, followed by hot air drying, and the freeze drying color is the lightest. Conclusion: Freeze drying can be used when high-end products are not considered for cost; solar energy drying is recommended when considering environmental protection and energy saving; traditional hot air drying is recommended for general industrial production.

Key words: galangal microwave drying; drying method; total phenol; total flavonoids; galangin; color; volatile components

Alpinia officinarum Hance is the dry rhizome of galangal, a genus of Gingeraceae. It is mainly produced in Guangdong, Hainan, Fujian, Yunnan, Taiwan and other places. It is one of the commonly used traditional Chinese medicines. Galangal has been reported to have strong pharmacological activity, and its extract has various biological activities such as antibacterial, anti-oxidation, anti-emetic, anti-cancer, anti-gastrointestinal ulcer, anti-thrombosis, hypolipidemic and cholesterol, anti-gastric mucosal damage and bronchial inflammation. In addition to being the most important raw material for the world famous Chinese medicine Wanjin Oil, it is also widely used in food, cosmetics and other medicines.

Studies have shown that the chemical components contained in galangal are very complicated. The active ingredients separated by foreign scholars are mainly volatile oils, flavonoids and diphenylheptanes, followed by glycosides, sterols and phenylpropanoids.

Galangal is a precious source of South medicine, distributed in the tropics and subtropics, but the quality and efficacy of galangal products vary greatly from region to region. Among them, the quality of galangal produced in Longtang Town, Xuwen County, Guangdong Province is the best. Ground galangal. Because post-harvesting galangal is not resistant to storage and mildew, the galangal in the Xuwen area is mostly exported to foreign countries. Therefore, the changes in physical and chemical properties during the drying process are important for the export quality of galangal. influences.

This study will compare the changes of total phenol, total flavonoids, galangin, volatile components and color difference of galangal tablets before and after hot air, freeze-drying, vacuum heating, sun, air drying and microwave, and find out the galangal It has a high preservation rate of active ingredients and is suitable for industrial production. It is used to guide the production of galangal and the production of dry products, and to obtain higher quality galangal pieces and dry powders.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply