- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research status of nut drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research status of nut drying

2018-11-22 10:36:54

Abstract: Microwave drying equipment in the initial processing of nuts after harvesting is the main factor affecting the efficiency of nut processing enterprises. In order to solve the problem of difficult drying of nuts, a set of nut drying process was proposed, which discussed the development status of nuts drying method and theory at home and abroad and the application status of drying technology in the nut industry. Research methods and results provide a theoretical reference for the research and development of nut drying processes.

Key words: nut microwave drying; drying technology; method; research status

It has a wide variety of nuts, rich nutritional value and high medicinal value, which is very popular among consumers. However, the nut shells, nuts, and drying characteristics of various nuts vary, resulting in different methods of drying. In recent years, domestic and foreign scholars have done a lot of research in the field of nut drying, but most of them focus on macadamia nuts, but there are few reports on other nuts drying.

The nut is dried mainly by controlling the external temperature, so that the outer temperature of the nut husk and the nut is higher than the temperature of the nut, and the temperature difference between the inside and the outside is formed to remove the water, so as to achieve the proper moisture for storing or eating the nut. Most of the nuts are dried by conventional methods such as natural drying, artificial drying, hot air drying and microwave drying.

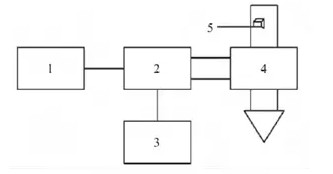

The microwave drying method refers to converting the power received by the microwave generator magnetron into microwave power by means of a waveguide device for transmission to the microwave heater to achieve the purpose of drying the material, and the moisture loss factor is much larger than the loss factor of other substances. Microwave heating utilizes the dielectric loss basis to cause the moisture in the material to evaporate rapidly by absorbing a large amount of microwave field energy.

Due to the rapid evaporative cooling of the surface moisture of the material, the surface temperature and moisture gradient of the material are much lower than the internal temperature and water gradient. The dual action causes a pressure gradient inside and outside the material, and the water is discharged from the inside to the surface under the action of the pressure gradient. It is evaporated again.

The higher the initial moisture content of the material, the greater the pressure gradient and the faster the drying rate. Microwave drying overcomes the shortcomings of other drying methods due to the first drying of the material surface to form a hardened shell to prevent moisture from moving outward. Most of the nut shells are hard, the drying time after harvest is long, time-consuming and laborious, and the mechanical drying method of nuts is not yet mature. Drying costs are also expensive, so the drying of nuts has become a major difficulty in the nut industry. The backwardness of the drying method has seriously restricted the development of the nut industry chain.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply