- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Methods on the Quality and Energy Consumption of Okra Crisp

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Methods on the Quality and Energy Consumption of Okra Crisp

2018-11-26 14:15:03

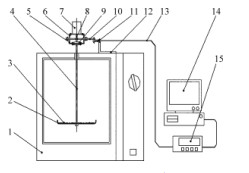

Abstract: In order to determine the best drying method of casual okra crisps, the research of far infrared drying, hot air drying, vacuum freeze drying, microwave drying equipment, vacuum freezing combined vacuum microwave drying and hot air combined with vacuum microwave drying on okra crisps Hardness, brittleness, color, shrinkage, drying time, energy consumption rate, and the effects of total flavonoids, total phenolics, and polysaccharide content.

The results showed that: the content of total flavonoids, total phenols and polysaccharides in vacuum freeze-dried okra crisps was the highest, but the taste was soft, not crisp, and the drying time was the longest, and the energy consumption was the highest; far infrared drying, hot air combined with vacuum microwave drying and hot air drying and brittle The content of total flavonoids, total phenols and polysaccharides in the strips decreased in turn, and the three dry brittle strips all had poor color, hardness and serious shrinkage;

The vacuum freezing combined with vacuum microwave drying and vacuum microwave drying of brittle strips has moderate hardness and crispness, and the content of total flavonoids, total phenols and polysaccharides is second only to vacuum freeze-dried brittle strips. The texture of okra crisps under two drying modes The difference in nutrient content was not significant (p > 0.05), but vacuum freezing combined with vacuum microwave drying time was 40 times that of vacuum microwave drying, and the energy consumption rate was about 5 times.

In general, the hardness, brittleness, color and nutrients of the vacuum microwave drying brittle strips are kept well, and the drying time is short and the energy consumption is low, which is suitable for the dry processing of the leisure okra crisps.

Key words: Okra microwave drying, drying method, quality, energy consumption rate

Okra, also known as croissant and tonifying kidney grass, is an annual herb of the genus Okra. It is native to Africa and is widely cultivated in Asia, southern Europe and the Americas. Okra is rich in protein, free amino acids, VC, VA, VE and mineral elements such as phosphorus, iron, potassium, calcium, zinc and manganese, especially flavonoids, polyphenols and polysaccharides.

Flavonoids and polyphenols have the functions of scavenging free radicals in the body, delaying aging, anti-cancer, anti-radiation and other biological activities. Polysaccharides can promote the excretion of organic substances in the body and reduce the accumulation of toxins in the body. However, the okra has a short shelf life and can only be stored for 2 to 3 days at room temperature. If it cannot be sold or processed in time, the loss of water and nutrients is more, and the fruit is prone to senescence. Domestic research on okra mainly focuses on its appearance, nutrient content, and planting conditions, and there are few studies on its dry products.

At present, dried okra products in the market include okra powder seasoning, health bag tea and fried okra crisps, etc. Seasonings and health bags can not be used as ready-to-eat products, and the products processed by frying are high in oil. The loss of nutrients is more, and it is more difficult to solve the adverse effects of oil oxidation on product quality. In recent years, fruit and vegetable chips have gradually entered the market and are increasingly favored by consumers. Some domestic enterprises are also targeting the market to actively plan fruit and vegetable dry snack food processing projects.

This study intends to select the texture, nutrient content, drying time and energy consumption rate as indicators to compare and analyze the effects of far infrared, hot air, vacuum freezing, vacuum microwave, vacuum freezing combined with vacuum microwave and hot air combined with vacuum microwave drying of okra. In the screening of the most suitable dry method of okra crisps, and provide reference for its industrial production.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply