- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Current status and development trend of rice flour drying technology

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Current status and development trend of rice flour drying technology

2018-11-26 14:58:20

[Abstract] Explain the current status of domestic rice flour drying processing technology, comprehensively analyze the advantages and disadvantages of open air drying, hot air drying, microwave drying equipment, vacuum freeze drying and combined drying technology in actual production and application, evaluate its development trend, and point out the future rice noodles. The development of drying technology should focus on the development of natural green energy and a new joint drying technology with low energy consumption and low cost.

[Key words] rice flour microwave drying; drying technology; development

Rice flour is one of the traditional staple foods in southern China and has a long history of production. Its origin is mainly distributed in southern areas such as Guangdong, Guangxi, Hunan, Hubei and Jiangxi. Rice flour is made from rice as the main raw material, soaked, refined, steamed, shaped, cooled, etc.; dry rice flour is not dried, dried rice flour, including powder, square powder and corrugated rice flour. Because rice flour has a long shelf life and is convenient for storage box transportation, the market is more extensive.

Drying is an important means to ensure the quality of rice noodles, and it is also a common food processing technology. The quick and effective drying method can quickly dehydrate and dry the rice flour after extrusion molding, prevent rejuvenation, and maintain good quality and long shelf life of the rice flour. The traditional rice noodle drying method is mainly natural drying and hot air drying. With the continuous development of science and technology, some new drying technologies such as microwave drying, vacuum freeze drying and combined drying are gradually being used for the research of rice flour drying. This paper reviews several typical drying techniques that are common at this stage, and provides a basis for the improvement of rice flour processing technology and the development of the industry.

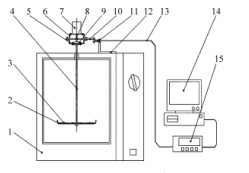

Microwave refers to electromagnetic waves with a wavelength of 0.1 mm to 1 m and a frequency of 300 MHz to 3000 GHz. The principle of microwave drying is to rely on high-frequency electromagnetic waves to initiate high-speed rotation of polar molecules such as water in the material, so that frictional heat is instantaneously generated inside the material, which causes the internal and surface of the material to simultaneously heat up, and promotes evaporation of water molecules from the material to achieve drying. the goal of. Microwave drying has the advantages of fast heating speed, short drying time, good selectivity, high energy utilization rate, good quality after drying, etc., and is widely used in the food field.

For example, Zhu Dequan studied the microwave drying characteristics and the best processing technology of corn. The experimental results show that the optimal process for microwave drying of corn kernels is: drying power 0.2 W/g, drying temperature 40 °C, wind speed 45 m/min. Drying the corn under these conditions has the least consumption capacity, and the dried corn is easy to store and has high utilization value. Li Yuanzhi et al. studied the microwave drying process of potato. The results showed that the brittleness of potato chips was proportional to the microwave power. In a certain range, increasing the power of microwave could increase the brittleness of potato chips.

Liu Chengmei et al studied the microwave drying of convenient rice flour, and found that microwaves with different powers have a significant effect on the diffusion coefficient of water, and the drying rate rises to the maximum in a short time. However, too high power tends to cause the local temperature of the material to be high, and excessive heating, irritability, etc., affecting the quality and even losing the edible property. Li Xinhua and other studies found that compared with the hot air dried rice noodles, the microwave reheating rice noodles had little difference between rehydration and food quality, while microwave drying time was much shorter than hot air drying.

Microwave drying also has some common problems, such as uneven drying, poor color and deformation of the product, and difficulty in controlling the final moisture content. The difference between the structure of the material itself and the distribution of the field strength of the microwave in the drying chamber will affect the balance of dehydration.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply