- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Processing Methods on the Quality of Gastrodia Elata

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Processing Methods on the Quality of Gastrodia Elata

2018-11-26 15:23:31

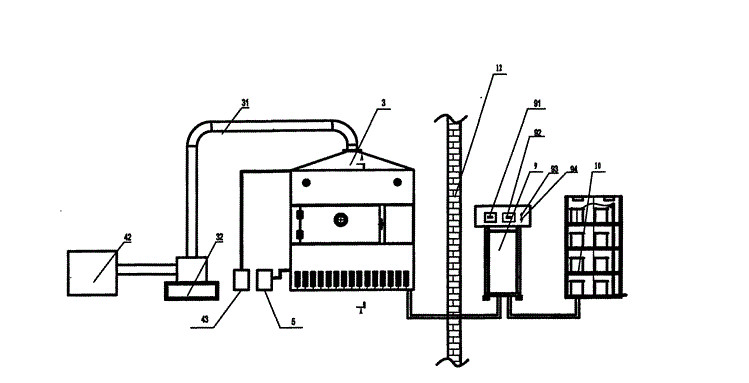

[Abstract] Drying, sulphur fumigation, hot air drying, microwave drying equipment, infrared drying and various combined techniques to dry Tianma medicinal materials, by comparing the traits, extracts and active ingredients of each sample, examine different drying methods for Tianma medicinal materials The impact of quality.

The results showed that the characteristics of the samples obtained by sulfur fumigation, hot air drying and hot air microwave drying were better; different drying methods had little effect on the leachate, and the content of the leachate after hot air drying treatment was higher; sulfur fumigation, microwave drying alone, Infrared drying alone causes a conversion of the stilbene glycoside component and a decrease in the content of the gastrodia elata polysaccharide. Comprehensive analysis of the traits of the medicinal materials, the content of active ingredients, production costs and other factors, the method of drying and processing the natural gas of the gastrodia elata is preferred by hot air drying or hot air microwave drying.

Key words: Tianma microwave drying; origin processing; drying method; traits; leachables; active ingredient content

Gastrodia elata is the dry tubers of the gastrodia plant Gastrodia elata Bl., which has the effect of calming the wind and stopping the phlegm, calming the liver and yang, and relieving the wind and the collaterals. After the harvest of fresh gastrodia, the water content is large, and it needs to be processed as soon as possible to avoid deterioration of the medicine. The traditional methods of processing Tianma are generally dry, smoked, dried, etc., with long processing time and cumbersome operation. Sulfur fumigation is the preferred method for processing Chinese herbal medicines at the grassroots level due to its low cost and easy operation.

Although traditional Chinese medicine can solve local problems after sulphur fumigation, it has been found through experimental research that sulphur fumigation of Tianma medicinal materials will cause changes in medicinal composition and SO2 residue. Therefore, looking for modern processing technology that can replace the sulfur fumigation method will ensure the safety and effectiveness of the clinical use of Tianma. According to the different drying principles of modern advanced technology, this paper puts the Tianma medicinal materials in one kind or in two or more different equipments for drying. By comparing the properties, extracts, and active ingredient contents of the gastrodia elata samples obtained by various drying methods, the best production method is preferred.

The steaming process determines: When the production is processed, the fresh gastrodia medicinal material needs to be sterilized and then dried. In the previous experiments, it was found that the content of active ingredients and extracts in the gastrodia elata samples obtained by the steaming method was significantly higher than that of the cooking method. Therefore, the pre-preparation treatment of different drying technology samples was steamed, and the steaming time was determined according to the size of the head. .

Determination of hot air conditions: According to literature research, gastrodin is more stable in heat, but if the temperature is too high during the early drying process of gastrodia elata, foaming will occur. Therefore, the hollow air is not foamed, and the appearance property is preferably an evaluation standard. The hot air drying temperature is determined to be 55 ° C by preliminary preliminary experiments.

Taking the appearance of medicinal materials, the content of extracts and the content of active ingredients as indicators, we investigated drying, sulfur fumigation, hot air, microwave, infrared, hot air microwave, hot air infrared, microwave infrared, hot air microwave infrared. The gastrodia elata medicine obtained by the dry processing technology is finally considered to be selected by hot air drying or hot air microwave combined method. The appearance characteristics of the gastrodia elata medicine are better, the content of the extract and the active ingredient is higher, and the quality is better.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply