- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Screening of the drying process of Anoectochilus

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Screening of the drying process of Anoectochilus

2018-11-26 15:42:21

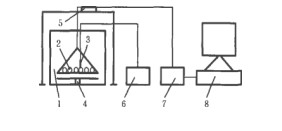

Abstract: Objectives The current literature has a method of drying golden lotus, and the optimal drying process is screened for later research. Methods The sensory quality (appearance, color, odor), energy consumption (unit energy consumption, drying time, total drying time), active ingredients (total flavonoid content, polysaccharide content) were obtained by three methods for hot air drying and microwave drying equipment.

The three drying methods of vacuum freeze drying were compared to select the optimal drying process of A. chinensis. Conclusion Based on the above three evaluation results, the vacuum microwave drying method is the most suitable drying method.

Key words: Golden Lotus microwave drying; sensory evaluation; energy consumption; active ingredient; optimal drying process

Drying is an old and new traditional Chinese medicine processing and storage method. In the early days of human beings, we learned how to treat Chinese herbal medicines by drying and drying. The ultrasonic drying and solar drying in modern times are more advanced. At present, hot air drying, vacuum freeze drying, vacuum microwave drying, spray drying, etc. have become the mainstream method for drying Chinese herbal medicines. The choice of drying method is particularly important for the maintenance of the appearance and medicinal ingredients of Chinese medicinal materials.

A. chinensis is a precious and medicinal plant of the people, and the whole plant can be used as a medicine. Fresh A. chinensis is not easy to store and transport, so the research on drying process is particularly important for the development of A. chinensis industry.

Hot air drying is the most commonly used drying process for Chinese herbal medicines. It has low cost and easy operation [5]. Microwave vacuum drying is short and easy to control, and can better retain the active ingredients of traditional Chinese medicine. Vacuum freeze-drying has good appearance for the product. The effect is to retain the heat sensitive ingredients in the product to the utmost extent. Therefore, this test uses the above three methods to dry it, in order to screen out the best method.

In this experiment, three drying processes, namely hot air drying, microwave vacuum drying and vacuum freeze drying, were used to compare the sensory quality, energy consumption and active ingredients of the golden lotus products. The test results show that:

(1) Sensory: The evaluation result of the golden clematis product obtained by vacuum freeze-drying is slightly better than the golden clematis product obtained by microwave vacuum drying, but the difference between the two is not significant, and both of the drying processes are superior. Hot air drying;

(2) Energy consumption: Microwave vacuum drying is obviously superior to hot air drying. Hot air drying is obviously superior to vacuum freeze drying. Microwave vacuum drying has the lowest energy consumption and the most cost saving;

(3) Quality: vacuum microwave drying and vacuum freeze drying are effective

The difference in composition retention is not significant, and both drying methods are superior to hot air drying in retaining active ingredients.

. Combined with the above analysis results, it can be seen that although vacuum freeze-drying is equivalent to microwave vacuum drying in the retention of active ingredients and is slightly better in sensory than microwave vacuum drying, it takes more time and power to vacuum freeze-dry at cost. The output is less, the production efficiency is much lower than microwave vacuum drying. Therefore, the comprehensive sensory, quality, cost and other factors lead to the conclusion that the best drying method for A. chinensis is microwave vacuum drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply