- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research and development trend of Chinese herbal medicine drying equipment technology

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research and development trend of Chinese herbal medicine drying equipment technology

2018-11-27 10:32:42

Abstract: Introduce microwave drying equipment, vacuum freeze drying technology, low temperature adsorption drying technology, heat pump drying technology, spray drying technology and other major Chinese herbal medicine drying equipment technologies. Combined drying can achieve high efficiency and energy saving of the drying process of herbs. The trend of development in the field of drying.

Key words: Chinese medicine microwave drying equipment; vacuum drying

Drying is an indispensable link in the processing and production of Chinese herbal medicines. The drying process directly affects the quality of Chinese herbal medicine products. During the drying process, time and temperature are important parameters, and the magnitude of the amount is closely related to the loss of effective ingredients and the degree of inferior quality. Correlation, therefore, the choice of drying equipment type and the setting of control conditions are especially important for the production and processing of traditional Chinese medicine.

The drying process of Chinese herbal medicines can be divided into traditional drying methods and modern drying methods according to technological development. Traditional drying methods are divided into dry, dried, and dry rooms, without special equipment. With the development of science and technology, the introduction of new technology into the drying equipment not only speeds up the drying speed, but also maintains the four-flavor and five-flavored medicinal properties required by traditional drying. Here are a few of the main drying techniques.

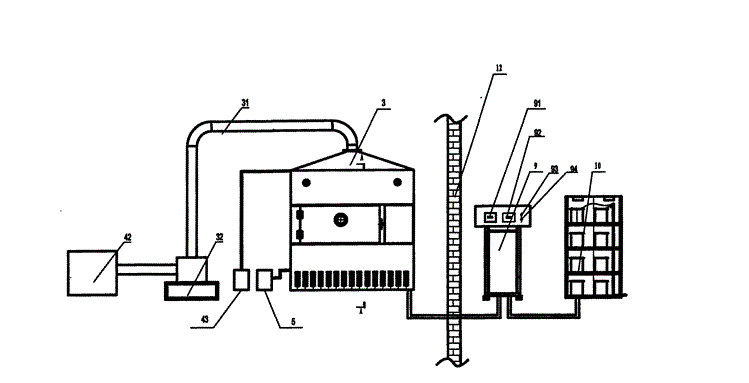

The basic principle of microwave heating and drying is to use high-frequency electromagnetic waves to interact with matter molecules to generate thermal effects, and convert microwave energy into medium heat energy to achieve drying effect. The frequency range is from 300 MHz to 300 GHz. The microwave drying system is mainly applied to microwave materials, power supply, waveguide device and microwave drying. It is not only suitable for aqueous substances, but also for organic solvents and inorganic salt drugs, such as ginseng, velvet, honeysuckle, yam, medlar, ginkgo, licorice and wormwood. Such herbs are not suitable for the drying of heat sensitive herbs.

Microwave medicinal drying minimizes the effective medicinal ingredients in Chinese medicinal materials, kills various molds and eggs in the medicinal materials, and prevents mold and insects from being stored. Microwave has different penetrating power for different materials. The thickness of the material affects the drying speed and effect, so microwave heating and drying are selective.

Drying of medicinal materials must be considered to maintain the original medicinal ingredients. In actual production, appropriate drying methods and equipment should be selected according to the nature of the medicinal materials. Whether the application of various drying techniques will affect the chemical composition, pharmacological effects and clinical efficacy of traditional Chinese medicine remains to be further studied. Combined drying to achieve high efficiency and energy saving in the drying process of medicinal materials is a development trend in the field of drying.

In the production, the characteristics of the dried product should be systematically analyzed, and the effects of temperature, humidity and pressure on the properties and characteristics of the Chinese herbal medicine should be mastered. According to the drying kinetics curve of the material, the drying process should be carried out in different drying stages. Improved, using a variety of combined drying. Hot air-vacuum drying combination technology, which has the advantages of high efficiency of hot air drying and good economic performance.

Hot air-microwave drying, with fast drying speed, high efficiency, complementary advantages, reducing energy consumption and improving product quality; solar energy - hot air - vacuum drying, can use natural energy, fast and hygienic. Energy conservation is an aspect of drying technology equipment. It is necessary to pay attention to the research of drying basic theory and introduce scientific research results in other fields (such as heat pipe technology, supercritical fluid technology, heat pump technology, computer intelligent technology, and pulsating combustion technology) to speed up. The use of energy-saving technology.

There are many kinds of Chinese medicinal materials, there are 11146 kinds of medicinal plants, 1581 kinds of medicinal animals, and 80 kinds of medicinal minerals. The parameters of different medicinal materials should be set in the control system to meet the needs of different types of medicinal materials. Limit the maintenance of medicinal ingredients, realize the online display of Chinese herbal medicines, and analyze and regulate the data in real time. The development of intelligent control systems with superior performance, remote monitoring and other Chinese herbal medicine drying equipment is the future development direction.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply