- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on New Technology of Microwave Drying and Drying of Green Hazel

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on New Technology of Microwave Drying and Drying of Green Hazel

2018-11-27 13:27:42

Abstract : Objective: To study the drying process of green scented plum and provide a basis for the establishment of a new processing method for green scented plum. METHODS: Fresh green mandarin plum was processed by microwave "drying" and drying method. The alcohol soluble extract, chlorogenic acid, hyperoside and isoquercitrin were used as evaluation indexes to discuss the microwave drying method for green buckwheat. The impact of quality.

Results: The microwave drying process was preferred, and the chlorogenic acid content in the microwave drying equipment was higher than that of the conventional dry samples, and there was a significant difference. Conclusion: Microwave drying method can effectively preserve the active ingredients of green buckwheat and improve the product quality of green buckwheat.

Key words : green buckwheat microwave drying; traditional drying

It is a dry flower bud of the genus Prunus mume (Sieb.) Sieb.et Zucc., which has the effect of opening and stagnation, detoxification and detoxification. The edible energy can “help the Qingyang gas rise” It is a traditional medicine and food dual-use Chinese medicine. Modern research has shown that green buckwheat contains chemical constituents such as volatile oils, flavonoids, phenolic glycosides, ester glycosides, and phenylpropanoids, which have antioxidant, anti-platelet aggregation, and melanin deposition.

It is mainly produced in Anhui, Hubei, Zhejiang and other places. In the investigation of its main producing area, it was found that the green buckwheat was blast-dried in the processing of the production area. When the temperature was low to dry, the temperature was dry to complete. Drying and drying operations are dispersed by farmers, lacking objective processing parameters, which makes the quality difference between different batches of green hazel samples are not suitable for industrial production. Therefore, it is necessary to explore more suitable processing methods to better ensure The quality of green plum is also suitable for industrial production.

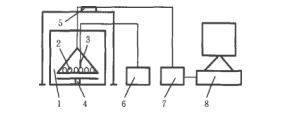

After consulting relevant literature and enterprise research, it is found that microwave drying technology is widely used in the production of food and medicinal materials. Therefore, the microwave drying method of green ume is studied for the problems existing in the traditional processing of sorghum production.

The traditional drying and drying is to first heat the surface of the object, and then increase the internal temperature by heat conduction, and it is easy to cause uneven heating of the material, which is easy to brown the flower medicine, and the microwave drying is special because of its heating method. Permeability heating can dry the material in a short time, and the heating is uniform, so that the color and quality of the product are improved. In addition, the microwave heating energy utilization rate is high, the heating efficiency is high, the drying process is easy to be automatically controlled, and it is suitable for industrial production.

In this study, the total amount of alcohol-soluble extract, chlorogenic acid content, hyperoside and isoquercitrin was used as the evaluation index, combined with the appearance traits of the product, combined with the research on the microwave drying process in the early stage of the laboratory, the microwave of the green buckwheat. The drying process is preferred and provides technical support for the industrial production of green hazel compared to conventional drying processes.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply