- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Techniques on the Quality of Fresh-cut Jujube Tablets

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Techniques on the Quality of Fresh-cut Jujube Tablets

2018-11-28 16:16:31

Abstract: The effects of six different microwave drying equipments on the bulk density, rehydration, total ketone content, total phenol content, color change and volatile components of jujube slices were investigated.

The results showed that the vacuum freeze-dried samples had the highest rehydration, total ketone content, total phenol content and volatile components, and the brightness (61.92 ± 0.44) and total color difference (0.67 ± 0.14) were not significantly different from the original jujube tablets, but the volatility The content of acetic acid in the composition is relatively high, accounting for 41.55% of the total composition, indicating that the quality of the freeze-dried sample is best except for the small flavor effect.

Compared with continuous microwave drying, the total ketone and total phenol content of the samples were significantly increased (p < 0.05), while the brightness value increased by 2.39 and the total color difference decreased by 2.68, indicating that the difference in quality between the two vacuum microwave drying samples was small. Heating can avoid excessive oxidation or degradation of nutrients caused by heat in the sample.

Atmospheric drying technology (hot air, infrared and intermittent microwave), it is easy to cause thermal oxidation or degradation, resulting in the degradation of ketones and phenolic components to about 55% of the original jujube tablets, the brightness value drops to 51.79, and the volatile components account for about 55%. 60% of the original jujube tablets, and will produce odor components such as decyl alcohol, furfural, etc., the dry quality of the jujube tablets is poor.

However, the atmospheric drying technique can improve the characteristic color of jujube and weaken the amount of acetic acid growth (the hot air dried acetic acid content only rises by 15.68%). Therefore, various drying methods can be comprehensively considered to form a composite drying technology to achieve complementary advantages. This study provides basic data for the improvement of drying and drying techniques for fresh-cut jujube tablets.

Key words: jujube tablet microwave drying, drying technology, quality

Juzychuus jujuba dates is a mature fruit of the genus Rhododendron. It is a kind of medicine and food. It is rich in polysaccharides, vitamin C, polyphenols, saponins and other functional components. It has anti-aging and immune immunity. Improve the gastrointestinal environment, anti-inflammatory, prevent cancer and other important effects.

There is a saying in the folks that “a date every day, the red color will not be old”, because of the special physiological effects of red dates, it is also favored by domestic and foreign markets. According to reports, nearly 99% of the raw materials consumed in the world are from China, so jujube has also become an important economic crop in China.

Due to the concentrated concentration of red jujube and mature season, the water content of fresh jujube after harvest is high, which makes the jujube extremely easy to be mildewed in storage, processing, transportation and sales, which seriously restricts the development of jujube industry. In order to ensure the quality of jujube, most of the postharvest red dates will be dried for storage and subsequent processing.

Due to the special structure of the jujube epidermis, such as the stratum corneum, waxy and thick-walled cells, it seriously hinders the evaporation of water inside the fruit, which makes the drying of the jujube less efficient and of lower quality. After the jujube slice treatment, it is beneficial to the internal moisture diffusion and evaporation, which can achieve rapid and efficient drying, and solve the problems of high energy consumption and poor quality of the whole jujube.

In addition, with the rapid development of the jujube industry, the traditional natural or hot air drying technology can no longer meet the development of the jujube industry. However, at present, fresh cut jujube tablets are mainly hot air drying, and a small amount involves infrared drying, vacuum drying, gas jet drying technology, etc. There are few reports on freeze drying, intermittent microwave drying, etc., and comprehensive comparison of several drying methods, clearly There are few studies on the effects of drying techniques on the quality of jujube tablets.

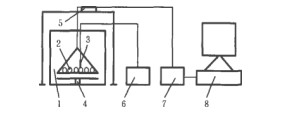

In this paper, we study the drying technology, compare the effects of hot air drying, infrared drying, intermittent atmospheric microwave vacuum drying, continuous vacuum microwave drying, intermittent vacuum microwave drying, vacuum freeze drying on the quality of jujube slices, and explore the most suitable jujube. The drying technique of the slice.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply