- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying research and parameter optimization of Pleurotus eryngii

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying research and parameter optimization of Pleurotus eryngii

2018-11-28 17:09:14

Abstract: The drying time and color difference were used as indicators, microwave strength, initial moisture content and slice thickness were used as experimental factors to study the water loss law of Pleurotus eryngii microwave drying equipment. The study found that the loss of water in the microwave drying of Pleurotus eryngii is two stages of heating and rapid water loss. The process parameters of microwave drying of Pleurotus eryngii are preferably 60% initial moisture content, 32 kW/kg microwave intensity and 3 mm slice thickness.

Key words: food processing; Pleurotus eryngii microwave drying

Pleurotus eryngii, also known as Pleurotus eryngii, is a new rare edible fungus that has been successfully cultivated in recent years. Pleurotus eryngii is rich in flesh, dense and uniform in tissue, crisp in texture, pleasant in almond flavor and taste like abalone, and is a kind of edible fungus with a more crispy and refreshing mouth than the cap. Mushroom King" "Dried Shellfish".

The edible part of Pleurotus eryngii is 100% rich in vitamin B, niacin, folic acid, pantothenic acid and various minerals. It contains 8 essential amino acids, which have the effect of lowering blood fat, blood pressure and beauty. Tumors also have a certain preventive and inhibitory effect, and integrate food, nutrition and therapy into one, which is deeply loved by consumers.

In this paper, the microwave drying of Pleurotus eryngii was studied, and the law of water loss was explored. The drying time and color difference were used as indicators, and the microwave strength, initial moisture content and slice thickness were used as experimental factors for orthogonal test to obtain microwave drying optimization of Pleurotus eryngii. The parameters are intended to provide technical guidance for the fine control of the drying process applied to production.

in conclusion

(1) Microwave intensity has a great influence on microwave drying of Pleurotus eryngii. Pleurotus eryngii microwave drying loses moisture in two stages, namely the heated heating stage and the rapid dehydration stage. During the heating and heating period, the temperature of the mushroom body rises obviously, the water drops slowly. The higher the microwave intensity, the faster the temperature rises of the mushroom body and the shorter the heating stage. In the fast water loss stage, the moisture content appears rapidly and almost linearly decreases, drying. The higher the temperature, the faster the rate of decline.

(2) Among the factors affecting the microwave drying of Pleurotus eryngii, the main order of the factors affecting the drying time is microwave intensity > initial moisture content > slice thickness. From the color of the product, the order of influence of each factor is slice thickness > microwave intensity > initial moisture content. Different slice thicknesses have a significant difference in product color.

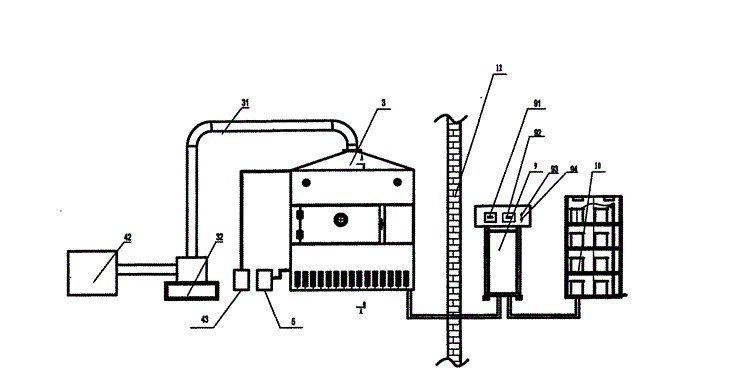

(3) The preferred microwave drying process parameters of Pleurotus eryngii are initial moisture content 60%, microwave intensity 32 kW/kg, and slice thickness 3 mm. Microwave drying is an efficient and energy-saving drying method. However, in production applications, microwave equipment is generally a closed type of tank. The moisture quickly released from the material cannot be discharged in time, and often stays in the tank, which affects the continued dehydration of the product. And may cause pollution. Therefore, for high-moisture fresh agricultural raw materials, joint drying is generally considered.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply