- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying method on quality characteristics of compound fermented venison with fruits and vegetables

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying method on quality characteristics of compound fermented venison with fruits and vegetables

2018-11-29 10:55:50

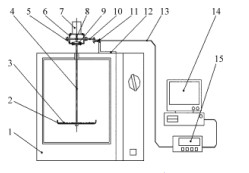

Abstract: In order to prepare high-quality fruit and vegetable composite fermented venison and determine the ideal drying method, the effects of hot air drying, vacuum drying and microwave drying on the drying characteristics, sensory quality and texture characteristics of compound fermented venison with fruits and vegetables were studied.

The results show that the microwave drying equipment has short drying time and high efficiency; the vacuum dried fermented venison has a moderate texture and good comprehensive quality, and the drying rate is slightly lower than microwave drying. Therefore, vacuum drying is the best drying method for the composite fermentation of vegan carp.

Key words: fruits and vegetables; venison microwave drying; fermentation; drying method; quality characteristics

Drying refers to the process of promoting evaporation of water from a product under natural or artificially controlled conditions. Drying can reduce the processing cost of food, maintain its flavor and color for a long time, and reduce the corruption of food. Hot air drying is a drying method in which heated air is used as a medium to heat the material, promote evaporation of water, and remove moisture on the surface of the material, and is widely used for drying various products.

Microwave drying has been successfully used in the processing of dried meat and meat, but its drying rate is fast, the drying end is difficult to control, and it is easy to cause excessive drying. The vacuum partial pressure of vacuum drying is reduced to avoid oxidative deterioration of materials and inhibit the proliferation of bacteria. At present, the research on the drying of meat products is mainly focused on a single drying method, and the preferred research on various drying methods is rarely reported.

Wang Xuerong et al. The effect of drying temperature on the tenderness of beef jerky showed that the tenderness of beef was worse with the increase of drying temperature; the combination of constant temperature and microwave was used for beef jerky, and the quality was better than traditional Process of beef jerky products; Zhang Guoshen et al. explored the effects of microwave vacuum drying on the physical and sensory properties of scallops.

This experiment mainly studies the effects of hot air drying, vacuum drying and microwave drying on the texture, drying characteristics and sensory quality of vegan husks. It is preferred to produce high quality fruits and vegetables with fast drying rate and good product quality. The development of a composite fermented venison carp provides an ideal drying method.

The difference in moisture content during microwave drying at the same power was significantly different. The microwave power is increased and the required drying time is shortened. When drying at 231 W and 385 W, the product reaches the drying end at 240 s and 150 s respectively. When drying at 539 W, the product is at 90 s. The drying end point can be reached.

As the microwave power increases, the rate of moisture content decreases. This is mainly because the power is increased, and the electric energy absorbed inside the material is increased, so that the temperature inside the material is higher than the surface temperature, and the temperature gradient is consistent with the concentration gradient of the water diffusion, that is, the direction of heat transfer and mass transfer are consistent, so that the drying time is remarkable. Shortened, water drops quickly.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply