- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Kinetic Model of Pecan

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Kinetic Model of Pecan

2018-11-29 16:36:56

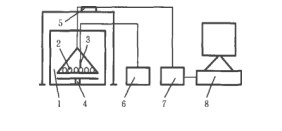

Abstract: Aiming at the problems of low efficiency, high energy consumption and poor quality of pecan nuts, the effects of microwave power and loading on the microwave drying characteristics of pecan nuts were studied by single factor experiment. According to the variation law of pecan nuts in microwave drying equipment, the variation of dry moisture content and water loss rate of pecan nuts under different microwave power and loading time were discussed, and the microwave drying kinetics model of pecan nuts was established.

The experimental results show that compared with the loading, microwave power has a great influence on the drying rate of pecan nuts; the microwave drying process of pecan nuts is divided into accelerated drying stage and slowing drying stage. Through analysis, the kinetic model of pecan nut microwave drying satisfies the Page equation. According to the drying experiment data, the dry model is solved by Matlab software, and the model coefficient is above 0.99.

Keywords: pecan nut microwave drying, drying characteristics, kinetic model

Pecan nuts are Chinese specialty nuts. Their nuts are not only rich in protein, oleic acid, linoleic acid and other unsaturated fatty acids, but also rich in essential amino acids and minerals. They have high nutritional value and economy. value.

However, drying has always been a weak link in the production of pecan nuts. It relies mainly on manual operation, low efficiency and high cost. Especially the temperature and water content of the drying process cannot be reasonably regulated, which may lead to insufficient coking or drying of the nuts, which seriously restricts The quality of pecan nuts and the development of the industry.

Pecan nuts are oval or broadly elliptical. The shells are thick and hard. There are multiple compartments inside the nut. The wooden membrane is well developed and the nuts are located in the compartment. Due to the complex structure of pecan nuts, the complex heat and moisture transfer between the nuts and the shell during the drying process and its cross-coupling effect, and with the fluid phase change, the internal temperature and water content changes are difficult to measure, and the drying process The mechanism of temperature transfer and water migration is still unclear.

At present, the production of pecan nuts is mostly by traditional hot air drying, the drying efficiency is low, the drying process is difficult to control, and the quality after drying is poor. Therefore, it is very urgent to explore non-traditional drying methods to improve the drying efficiency and dried fruit quality of pecan nuts. Microwave fields have a significant effect on promoting the abnormal evaporation of materials, rapid movement and reducing drying energy consumption, and are easy to control.

There has been research on microwave drying at home and abroad very early, but there are not many studies on nuts. Therefore, using microwave technology to study the heat and mass transfer characteristics of pecan nuts, to explore the movement law of water in nuts, establish the kinetic model of microwave drying of pecan nuts, to automate the drying process of pecan nuts and improve the quality of dried fruits. To lay the foundation for improving drying efficiency and reducing drying energy consumption.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply