- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying method on the characteristics of lotus root starch

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying method on the characteristics of lotus root starch

2018-11-30 15:04:40

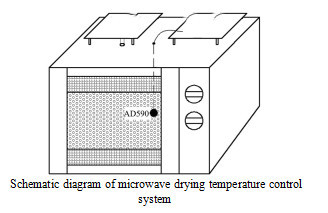

Abstract: Taking lotus root as the test object, the drying time, brightness, microstructure, crystal type, viscosity, stability of condensation and freeze-thaw stability of lotus root starch were studied by four different drying methods: hot air drying, microwave drying, vacuum microwave drying and infrared drying. Sexuality and transparency impact.

The results showed that the X-ray diffraction patterns of lotus root starch treated by hot air drying, microwave drying equipment, vacuum microwave drying and infrared drying were the same, and the crystal types were all B-type structures.

The hot air drying and infrared starch particles are irregular in shape, the surface is rough, there are obvious pits, the agglomeration and cracks between the particles are serious, and the appearance quality is extremely poor. The microwave drying and vacuum microwave drying of the starch, the overall structure of the large particles is an ellipsoid type. The small particles are spherical, no agglomeration, and the vacuum microwave drying lotus root starch particles are relatively complete, the outline is clear, and the surface is smooth.

Four kinds of drying methods were used to treat lotus root starch. The vacuum and microwave drying starch had the best brightness and stability, and the transparency was the lowest, while microwave drying had the shortest drying time and the best freeze-thaw stability. Comprehensive analysis, vacuum microwave drying method is better than the other three methods, can be applied to the industrial production of lotus root starch and starch products processing.

Key words: lotus root microwave drying, lotus root starch, different drying methods, characteristics

Nelumbonucifera Gaertn is a perennial plant of Nymphaeaceae. It has been cultivated in China for more than 3,000 years. The domestic cultivation of lotus root is more extensive. The starch of lotus root is the main nutrient component with a content of 10% to 20%. China's lotus root resources are abundant. Lotus roots are processed into starch, which can be used as an important raw material for food processing industry. It has great resource advantages and development prospects.

There are some reports on the research of lotus root starch at home and abroad. Tian Cuihua et al. concentrated on the characteristics of crystal, granule, aging and gelatinization of lotus root starch. Song Zhe carried out the fine structure, digestibility and water molecule mobility of lotus root starch in different periods. the study.

Qian Wenwen et al. Study on the particle morphology and rheological properties of different varieties of lotus root starch. Liu Min et al. investigated the effect of hydrophilic colloid on starch properties, and studied the different additions of xanthan gum and konjac gum. Starch gelatinization, rheology, texture characteristics and microstructure changes.

Chen Qiaoli et al. investigated the effect of high static pressure on the physical and chemical properties of lotus root starch. Tujing et al. used non-infrared spectroscopy to nondestructively detect the starch content of lotus root. Deng Qing et al. used lotus root starch as raw material, cooking, texture and sensory as indicators. The effect of lotus root starch on the quality of the fans, Li Xiteng et al. At present, the research on the difference of the characteristics of lotus root starch with different drying methods has not been reported.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply