- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Methods on the Quality of Traditional Chinese Medicine Formula Flow Extract after Drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Methods on the Quality of Traditional Chinese Medicine Formula Flow Extract after Drying

2018-12-01 10:06:53

Abstract : The effects of different drying methods on the dry extract obtained after drying the traditional Chinese medicine preparation extract were compared.

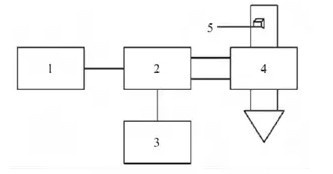

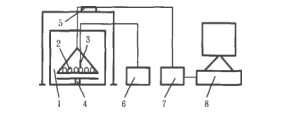

Vacuum dry, microwave drying and spray drying were used to dry the extract of compound blue silver granules, compound sputum capsules and anti-inflammatory degreased tablets. The traits, extract yield and index components were evaluated. Indicators, to investigate the effect of different drying methods on the quality of traditional Chinese medicine preparation thick paste after drying.

The dry extract obtained by spray drying is the lightest, the microwave drying equipment is the second, the vacuum dry dry extract is the darkest; the microwave drying and vacuum drying yield is higher, the spray drying yield is generally lower; The index, the dry extract of the dry extract index component is significantly higher than the other two drying methods.

Different drying methods have an effect on the properties, yield and content of the dry extract. In the actual process research, the drying method must be screened.

Key words: thick paste microwave drying; vacuum drying; spray drying; ultra performance liquid chromatography; drying method

The production of traditional Chinese medicine preparations often involves the drying process of thick paste. Common drying methods include drying method, vacuum drying method, microwave drying method, spray drying method, freeze drying method and the like. The drying method has a great influence on the quality of the preparation.

In this experiment, compound blue silver granules, compound sputum capsules and anti-inflammatory degreased tablets were used as research objects. Three hospitals were used to dry the three Chinese herbal medicines in three different drying methods. The traits, extract yields and indicators were used. The content of the ingredients was used as an evaluation index to compare the effects of different drying methods on the quality of the thickened traditional Chinese medicine preparation.

From the observation of the dry extract properties, the dry extract obtained by spray drying has the lightest color, and the dry extract obtained by vacuum drying has the deepest color, the gelatinization phenomenon of the extract, and the burnt smell; the extract yield rate, microwave and vacuum The dry paste yield is relatively close, and the spray drying yield is the lowest. According to the index component content, the dry extract extract component content of spray drying is significantly higher than the other two drying methods (measured per gram of dry extract), vacuum The lowest drying.

The three traditional Chinese medicine preparations selected in this trial have established their content determination methods when establishing the quality standards for hospital preparations. Therefore, this test directly measures the content and compares the effects of different drying processes on the quality of traditional Chinese medicine preparations.

In the spray drying, the compound capsule thick paste has poor fluidity of the primer, easy to stick to the wall, loose structure and easy adhesion, and can not complete the preparation of the spray-dried product. Therefore, it has not been spray-dried to prepare a dry extract.

When the dry extract powder is prepared by a small spray drying apparatus, there is a phenomenon that the powder is blown out of the tuyere, so that the yield of the spray-dried extract is affected.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply