- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Microwave Drying Conditions on Drying Characteristics of Raspberry Pulp

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Microwave Drying Conditions on Drying Characteristics of Raspberry Pulp

2018-12-03 13:39:44

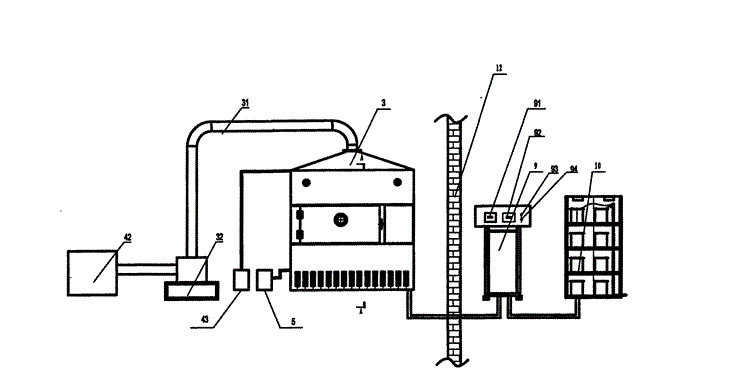

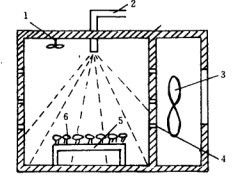

Absrtact: In order to study the heat and mass transfer characteristics of microwave drying raspberry pulp, using raspberry as raw material, the central composite experimental design method was adopted to study the effects of drying conditions on the temperature, moisture content and dielectric properties of the material, and to analyze the heat and mass transfer process in the process of microwave drying equipment.

The results showed that the dielectric constant and dielectric loss factor increased in the early stage of microwave drying, which increased the microwave energy absorbed by the material. The temperature of the berry increased from room temperature to 70 C, and the moisture content did not change significantly. In the middle stage of drying, the dielectric constant and dielectric loss factor increased first and then decreased.

Therefore, the microwave energy absorbed by the material increases first and then decreases, the moisture content of the pulp decreases from 90% to 40%, and the temperature changes are not obvious. In the later drying stage, the dielectric constant and dielectric loss factor decrease, the microwave energy absorbed by the material decreases, the moisture content of the pulp slowly drops to about 15%, and the temperature continues to rise. Microwave drying method can effectively improve the drying speed of high viscosity pulp.

Key words: microwave drying of raspberries, dielectric properties, heat and mass transfer

The moisture content of fresh raspberry fruit is about 90%. Its texture is soft and fragile, and it is difficult to transport and store. Drying treatment is a feasible method to prolong the storage period of raspberry. Microwave drying has fast heating rate and strong heat transfer ability; foam drying technology is suitable for materials with high sugar content and high viscosity.

Microwave drying technology has been widely used in fruit and vegetable processing and agricultural products, such as mango, papaya, melon, Hami melon and so on. At present, domestic and foreign scholars have done some research on the heat and mass transfer process of microwave drying. In order to simplify the calculation, the physical parameters are regarded as fixed values, but correction factors should be added to reduce the deviation from the actual situation, and considering the dielectric properties of materials changing with temperature and moisture content, the process of microwave energy absorption and conversion of materials can be accurately analyzed.

This paper intends to reveal the mechanism of heat and mass transfer in drying process. The research contents are as follows: The effects of microwave drying conditions on material temperature, moisture content and dielectric properties are studied; the regression model of dielectric properties and temperature, moisture content is established, and the heat and mass transfer process in microwave drying process is analyzed.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply