- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Methods on Quality of Toona sinensis Sprouts

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Methods on Quality of Toona sinensis Sprouts

2018-12-06 11:28:20

Absrtact: The effects of four drying methods on the quality of Toona sinensis sprouts were studied by sensory evaluation and determination of main nutrient contents, including hot drying, microwave drying equipment, vacuum drying and vacuum freeze drying.

The results showed that vacuum freeze-drying could maintain the main nutrient components of Toona sinensis seedlings and sprouts to the greatest extent. After drying, the chlorophyll content in Toona sinensis seedlings and sprouts reached 14.0081 mg/g-1, the vitamin C content reached 2.6203 mg/g-1, and the amino acid nitrogen content reached 24.33.

The protein content of 40mg g-1 sample reached 79.0076 ug, which was higher than other drying methods, and the sensory quality of Toona sinensis sprouts after drying was better; the comprehensive effect of vacuum drying was slightly worse than vacuum freeze drying; the loss of vitamin C by microwave drying was larger, and the comprehensive effect of microwave drying and hot drying was worse. 。

Key words: microwave drying of Toona sinensis sprouts; nutritional components; sensory quality

Toona sinensis is a precious woody vegetable in China. It can be cultivated by soilless cultivation of Toona sinensis Seeds under light conditions. It has the characteristics of crispness, tenderness, fresh green and strong fragrance. Toona sinensis seedling sprouts are mostly used as condiments for salad vegetables. However, it is not easy to keep fresh after sale and before consumption, even in refrigerators, the effect is not good. Ideal.

The proper drying method and technology for Toona sinensis sprouts can not only maintain its original color, fragrance, taste and nutritional components, but also be easy to preserve and carry. It can be used as ready-to-eat, convenient condiment and has great practical value.

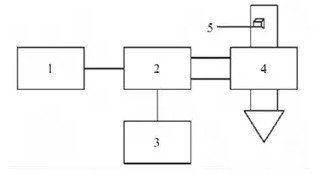

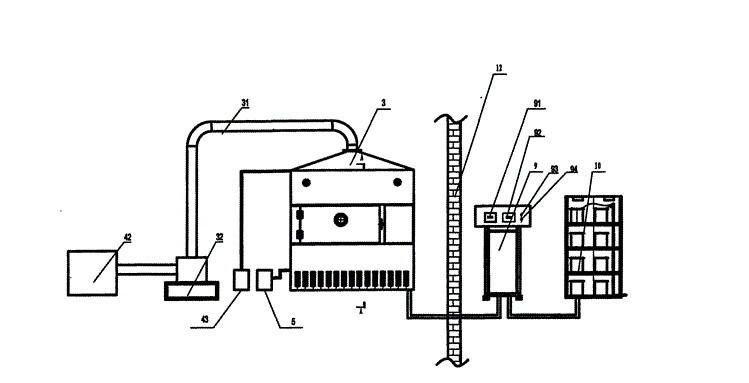

Different drying methods will have different effects on the quality of Toona sinensis seedlings and sprouts. Four drying methods, hot air drying, microwave drying, vacuum drying and vacuum freeze-drying, were used to carry out drying experiments, in order to find suitable drying methods and provide technical support for its drying and processing.

Compared with different drying methods, vacuum freeze-drying can keep the color, shape and fragrance of Toona sinensis seedlings and sprouts better. After drying, the change rates of three basic color values of Toona sinensis seedlings and sprouts were 0.44%, 0.72%, 0.24%, and the change rates of length and diameter were 4. 10% and 32.02% were better than other drying methods. The rehydration rate of Toona sinensis sprouts after vacuum freeze-drying was 51.05%, which was higher than other drying methods. The color, shape and fragrance of Toona sinensis sprouts were better restored after rehydration.

In terms of nutrient composition, the main nutrient contents of Toona sinensis sprouts after vacuum freeze-drying were higher, chlorophyll content was 14.0081 mg g-1, vitamin C content was 2.6203 mg g-1 and amino acid nitrogen content was 24.3340 mg g-1. The protein content reached 79.0076 ug, which was higher than other drying methods. Vacuum freeze-drying is a feasible and practical method for drying sprouts of Toona sinensis seedlings.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply