- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of different drying methods on the quality of dried chicken leg mushroom products

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of different drying methods on the quality of dried chicken leg mushroom products

2018-12-06 11:42:26

The main purpose of this paper is to study the quality changes of Coprinus comatus under different drying methods. Firstly, the colour protection pretreatment of Coprinus comatus was carried out, and then hot air drying, vacuum drying and microwave drying equipment were carried out respectively. The sensory, rehydration properties and nutrient loss of Coprinus comatus were compared. It was concluded that the quality of Coprinus comatus was the best under vacuum drying.

Key words: Microwave drying of Coprinus comatus; Dry products; Treatment of color fixative; Drying method; Quality; Effect

Coprinus comatus is a rare edible fungus with great potential for artificially development and production in recent years. It has been identified by WHO and FAO as one of 16 rare edible fungi with natural, nutritional and health functions. Coprinus comatus has delicious taste, rich nutrition, and has the function of improving immunity, and has anti-cancer effect. The growth rate is fast, the primordium can reach physiological maturity 3 to 5 days after formation, and the mature fruiting bodies are easy to open umbrellas and autolysis, which greatly reduces their edible value.

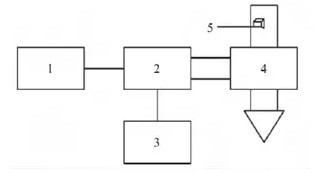

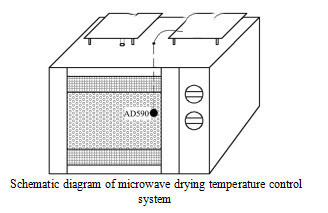

The process of drying Coprinus comatus can fully preserve its original nutrient composition and flavor even if the moisture content in the coprinus comatus is reduced to less than 11.5%. The effects of different drying temperature and time on the quality of fresh chicken leg mushroom were analyzed by three drying methods: hot air drying, vacuum drying and microwave drying. The effects of different drying methods on the quality of dried chicken leg mushroom products were studied by establishing drying curve and determining physical and chemical indexes of materials under different drying methods.

In the orthogonal experiment, the best combination selected according to the test results is A3B3C2D1, which can effectively inhibit the browning of Coprinus comatus. That is to say, the best preservation agent for Coprinus comatus is 0.10% citric acid, 0.10% sodium chloride, 14 mmol/L cysteine and 0.06% sodium isoascorbate.

The sensory organs of vacuum drying products are better than microwave drying and hot air drying, and basically keep the shape of Coprinus comatus before drying. The rehydration ratio is 4.2, which is significantly higher than the other two drying methods. After rehydration, the product is soft and elastic, and keeps the original fragrance of Coprinus comatus. The nutritional value of vacuum drying products is also better than the other two drying methods. Through hot air drying, vacuum drying and microwave drying of Coprinus comatus, it is concluded that microwave drying is the most efficient and time-saving. Comprehensive evaluation showed that the quality of dried chicken leg mushroom products obtained by vacuum drying method was the best, followed by microwave drying and hot air drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply