- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of microwave power on quality of dried ready-to-eat prawns

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of microwave power on quality of dried ready-to-eat prawns

2018-12-06 14:46:55

[Objective] To investigate the effect of microwave power on the quality of dried prawns after vacuum microwave drying. [Method] After blanching and seasoning, the shrimp was dried by vacuum microwave drying technology. The rehydration ratio and water activity of dried shrimp were determined.

[Result] The results showed that when the loading capacity was 100 g, the vacuum degree was 7.37 kPa and the moisture content was 15%, the rehydration ratio and water activity of shrimp products dried by 250, 500, 750 and 1 000 W microwave power were determined respectively, and the optimum microwave power was 500 W.

[Conclusion] Microwave drying equipment has certain influence on the quality of dried samples, which can provide reference for vacuum microwave drying of other aquatic products.

Key words: microwave drying of prawns; vacuum microwave drying; drying

Penaeus vannamei is one of the most important aquaculture products in China. Its annual yield is high and its economic value is high. However, after death, shrimps are easily corrupted by microorganisms and endogenous enzymes, and black-out phenomenon occurs under the action of polyphenol oxidase, and its shelf life is very short.

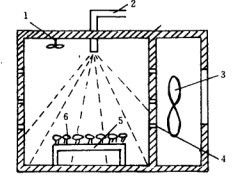

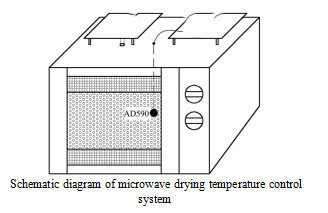

Vacuum microwave drying is a drying technology using microwave and vacuum combined drying. It not only makes full use of the characteristics of microwave drying, which is fast and easy to control, but also uses water vapor to evaporate rapidly under vacuum conditions, which can better maintain the original flavor of food.

At present, some scholars have applied vacuum microwave drying to the drying of some aquatic products. Zhang Guochen and others used vacuum microwave drying to drying scallop pillars, and found that the quality of products obtained by vacuum microwave drying was better than that by hot air drying and natural drying, and the microwave power and vacuum degree had great influence on the quality of scallop pillars.

Zhang Changsong et al. studied the technology of vacuum microwave drying of corrugated Paphia clam meat. The results showed that compared with hot air drying and natural drying, vacuum microwave drying was faster, shorter and the product quality was higher. Zhao Wei et al. studied the kinetics of vacuum microwave drying of Penaeus vannamei. It was found that microwave power and loading had a great influence on the rate of dehydration of shrimp meat.

The effect of vacuum microwave drying on the quality of shrimp meat was observed in order to explore the best technology of vacuum microwave drying for shrimp meat.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply