- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Microwave Drying Conditions on the Content of Sesame Matter in Green Pepper and Its Technological Optimization

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Microwave Drying Conditions on the Content of Sesame Matter in Green Pepper and Its Technological Optimization

2018-12-06 15:33:10

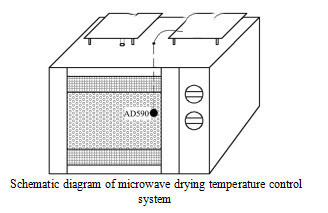

Absrtact: The microwave drying process of fresh "Jiuyeqing" green pepper was optimized by response surface methodology (RSM). The effects of microwave power, spreading amount and microwave time on the content of numbness substances in green pepper dried by microwave were investigated. The suitable influence range was determined by single factor test.

On the basis of single factor experiment, the optimum experiment design was carried out according to Box-Behnken central combination experiment design principle, and the regression model of microwave drying was established by using Design-Expert.V.8.0.6 software. The process of microwave drying green pepper was studied by setting the maximum content of sesame substance. Conduct index optimization.

The results showed that the optimum conditions of microwave drying equipment for green pepper were microwave power 357.78 W, spreading amount 203.38 g and microwave time 49.14 s. Under these conditions, the content of sesame substance was 24.328 7 mg/g, and the validation experiment was carried out under the optimum conditions. The error between the validation results and the optimum results was 1.18%. The result is reliable.

Key words: pepper microwave drying; response surface methodology; numbness substances; process optimization

Zanthoxylum bungeanum L. is a plant of the genus Zanthoxylum in Rutaceae. It originated in China and is now distributed all over the world with about 250 species. Zanthoxylum bungeanum has the efficacy of killing insects, relieving itching, warming pain and removing wind and dampness. Pepper numbness substance has the functions of anesthesia, analgesia, lowering blood lipid and protecting gastrointestinal tract. At the same time, it has the physiological activities of anti-cancer, anti-oxidation, wrinkle removal and so on.

However, green pepper harvesting has seasonal characteristics and is not resistant to storage, while dry green pepper has a positive impact on prolonging storage period. Therefore, pepper drying plays an important role in pepper industry. At present, pepper drying mainly includes natural drying and other drying methods. Natural drying does not require investment, is inexpensive, and is not limited by the site, but is vulnerable to weather conditions.

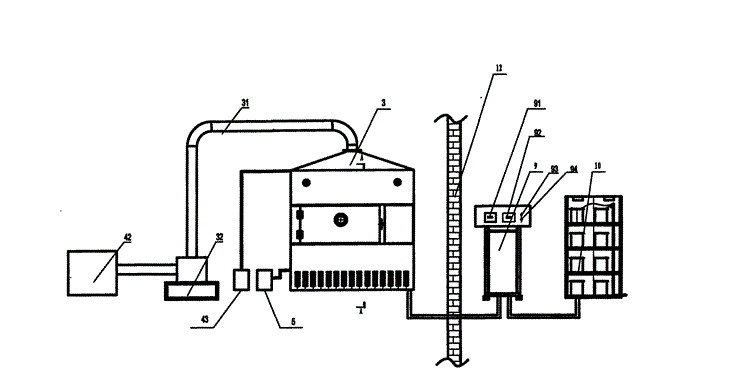

The research of pepper drying includes hot air drying, microwave drying, microwave vacuum drying, etc. Microwave drying has the characteristics of uniform heating, fast speed, high efficiency and easy to industrialize application. It has application value in industrial drying production of pepper, and gradually applied.

In the research of microwave drying of Zanthoxylum bungeanum, the main focus is on mathematical model and microwave drying characteristics. In the quality aspect, the main influence is external quality and chlorophyll content. The research on the influence of the content of pepper numbness substance on microwave drying conditions has not been reported, and the content of pepper numbness substance is an important quality index of dry Zanthoxylum bungeanum bungean Mark.

Therefore, the microwave drying experiments of green pepper were carried out to study the effects of different microwave drying conditions on the content of pepper spicy substances, and the optimization experiments were carried out. It is of great significance to improve the quality of dry pepper, and at the same time, it provides a theoretical basis for the industrial application of microwave drying technology of Chinese pepper.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply