- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Advances in drying technology of jujube

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Advances in drying technology of jujube

2018-12-11 11:54:29

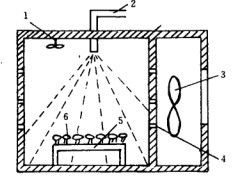

[abstract] Microwave drying equipment is one of the deep processing methods in jujube industry. In this paper, several main drying technologies of jujube in China were introduced, and their drying principles, system composition and technical characteristics were expounded. At the same time, the future development trend of jujube drying technology in China was pointed out.

[keywords] jujube microwave drying; drying technology; research status; development trend

Red jujube, also known as Chinese jujube, jujube and spine jujube, is the mature fruit of jujube tree of Rhamnaceae. Jujube is sweet and unique in flavor. It not only contains rich nutrients, but also has the earliest medical and health value in China. It is often used in traditional Chinese medicine. It has the functions of tonifying blood and qi, anti-cancer, brain-strengthening, protecting liver, detoxifying drugs and stomach, strengthening spleen and body.

As a unique fruit and vegetable resource in China, jujube has absolute advantages in planting area, variety and yield. At present, China has the vast majority of the world's excellent varieties of jujube, and the output of jujube accounts for about 95% of the world's total output, planting area is wide, mainly distributed in Shanxi, Hebei, Shandong, Shaanxi, Xinjiang and Henan.

In recent years, due to its special geographical location and environment, the jujube industry in Xinjiang has developed rapidly, and its jujube has gradually occupied the high-end market because of its high sugar content, large grains, thick flesh and beautiful appearance. Jujube contains many trace elements and rich nutrients, and has unique nutritional and medicinal value. However, fresh jujube can be stored in natural conditions for only a few days after harvest, and its pulp will quickly brown or rot.

Therefore, at present, the main products of Chinese jujube are dried jujube, and the proportion of dried jujube is more than 90%. This paper introduced the working principle, technical characteristics, system composition and technical research status of several main drying technologies of jujube, and pointed out the future development trend of jujube drying technology.

The combined drying technology of jujube will develop along the direction of effective utilization of energy, improvement of product quality and yield, reduction of environmental impact, safe operation, easy control and large-scale. Therefore, the future development of combined drying technology of jujube will focus on the following aspects.

(1) Combination drying process and determination of drying moisture conversion point. Because of the great difference in the types and tissue state of jujube, the combined drying process of different jujube is not fixed, so it is necessary to optimize the process parameters and drying moisture conversion point to achieve the best drying effect.

(2) Improvement of combined drying equipment. With the rapid development of science and technology, all kinds of drying equipment themselves are constantly improving. The multi-functional combined dryer is the future direction of development.

Automatic control of combined drying process. On the basis of determining the best combined drying process, the whole process automatic control is the inevitable development trend of combined drying technology in the future.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply