- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Orthogonal Test on Microwave Drying of Funing Pills

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Orthogonal Test on Microwave Drying of Funing Pills

2018-12-13 15:31:01

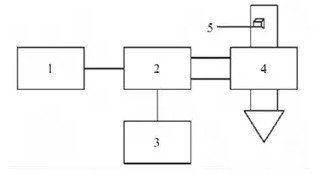

ABSTRACT: OBJECTIVE To screen the optimum technological conditions of microwave drying equipment for Funing pills. METHODS The water content, microbial limit and dissolution time of Funing Pills were investigated by orthogonal test, taking material transmission speed, material thickness and drying temperature as indexes.

Results Microwave drying of Funing Pills was carried out at a speed of 0.4 m/min, a thickness of 6 m m and a drying temperature of 70 C. CONCLUSION The microwave drying process of Funing Pills is ideal.

Key words: orthogonal experiment; microwave drying of Funing pills

Funing Pill is a concentrated water pill developed by our hospital for the treatment of premenstrual tension, chronic adnexitis, chest pain, breast disease, dysmenorrhea, menstrual headache and other diseases. It consists of 15 traditional Chinese medicines, such as Paeonia lactiflora, Bupleurum, Fructus Aurantii, Angelica sinensis, Xiangfu, Achyranthes bidentata, etc.

The traditional drying method is used in the original preparation process standard. Because the traditional drying process is time-consuming, inefficient and low productivity, microwave drying equipment was purchased in our hospital in 2007. In this paper, the optimum technological parameters of microwave drying Funing Pills were obtained by means of orthogonal test, taking the material transmission speed, material thickness and drying temperature as indexes, and comprehensively investigating the moisture content, microbial limit and dissolution time of Funing Pills.

The main influencing factors of moisture are material transmission speed and drying temperature, while the thickness of material is the secondary factor. The moisture content should be controlled at 4%-6%. The main influencing factors of microbial limit are drying temperature. There is no significant difference in the effect of each factor on the dissolution time.

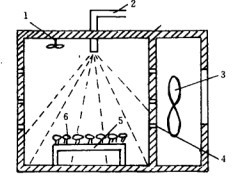

Microwave drying temperature has significant difference in water and microorganism control, especially in microorganism control. Compared with wet pills, the number of bacteria is significantly reduced. After microwave drying and sterilization, no fungi are detected. There is a significant difference between material transmission speed and water content. The slower the transmission speed is, the longer the microwave drying time is, the lower the moisture content is. The optimum conditions for microwave drying of Funing Pills were as follows: material transmission speed 0.4 m/min, material thickness 6 m m, drying temperature 70 C.

Microwave drying is superior to traditional oven drying and sterilization. It has the advantages of short time, low energy consumption, simultaneous drying and sterilization, high product quality, and can realize continuous and automatic production. Because of its high production efficiency and cost saving, microwave drying has replaced traditional oven drying in our hospital.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply