- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Methods on the Content of Effective Components in Bupleurum chinense

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Methods on the Content of Effective Components in Bupleurum chinense

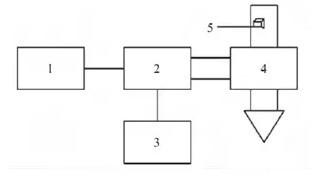

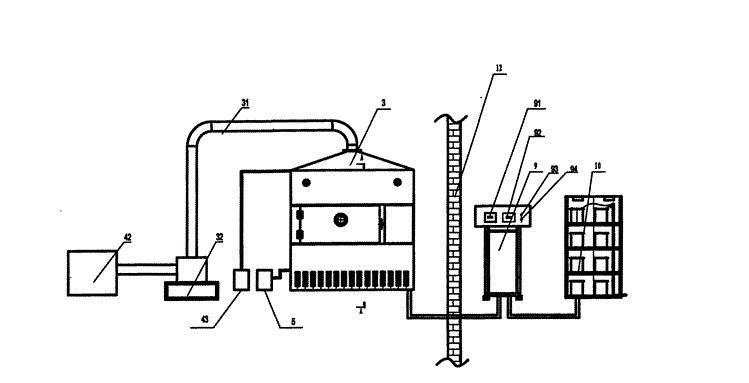

2018-12-14 11:32:31Objective: To study the effects of different drying conditions and treatments on the content of active ingredients in fresh roots of Bupleurum chinense so as to provide basis for determining the best drying method and improving the quality of Bupleurum chinense. Methods: Radix Bupleuri samples were dried by five methods: sun drying, shade drying, 50 C drying, 100 C drying and microwave drying.

The content of ethanol-soluble extract was determined by hot leaching method, saikosaponin a and D in Bupleurum chinense were determined by HPLC, total saikosaponin in Bupleurum chinense was determined by spectrophotometry, and the content of effective components in Bupleurum chinense was comprehensively evaluated by subordinate function analysis under different drying methods.

Result: Different drying conditions and treatments had significant effects on the content of active ingredients in Bupleurum chinense. The comprehensive evaluation results showed that the order of the content of active ingredients in Bupleurum chinense under different drying methods was: 100 C drying > Microwave Drying Equipment > shade drying > sun drying > 50 (?) CONCLUSION: The best drying method for Bupleurum chinense is drying at 100 C, followed by microwave drying.

Key words: Bupleurum chinense microwave drying; drying method; active ingredient content

Bupleurum chinense is a perennial herb of Umbelliferae Bupleurum. Its dry root is a traditional Chinese medicine, commonly known as "Bupleurum chinense", and its main active ingredient is saikosaponin. The relationship among active ingredients, pharmacology and clinical application of Bupleurum chinense is the focus of current research.

Different drying methods of traditional Chinese medicine have different effects on its appearance, odor and composition. Traditional drying methods have some disadvantages, such as drug contamination and weather influence, which may lead to the deterioration of Bupleurum chinense, the change of medicinal properties, the loss of effective ingredients and so on, resulting in the decline of its quality.

In view of this, this study used fresh roots of Bupleurum chinense as experimental materials, using five drying methods: sun drying, shade drying, microwave drying, 50 ~C drying and 100 ~C drying. Through the determination of alcohol-soluble extracts, total saponins of Bupleurum chinense, saikosaponin a and D content, and making a comprehensive evaluation, the most suitable drying method for Bupleurum chinense was screened out, in order to provide a theory for the processing of Bupleurum chinense origin. Basis.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply