- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Bamboo Shoot Drying Technology and Its Effect on Bamboo Shoot Quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Bamboo Shoot Drying Technology and Its Effect on Bamboo Shoot Quality

2018-12-14 11:58:12

Bamboo shoot is a traditional green forest vegetable with abundant nutrition. Drying is one of the main processing methods of bamboo shoots. In this paper, the application of hot air drying, vacuum freeze drying, microwave drying equipment in bamboo shoot drying and the effects of different drying technologies on the color, texture, nutrient composition and rehydration of bamboo shoots were summarized. The existing problems in current research were pointed out, and the development prospect of bamboo shoot drying technology was prospected.

Key words: bamboo shoot microwave drying; drying technology; quality

Bamboo shoots, also known as bamboo sprouts, bamboo buds and bamboo embryos, are the generic name of the tender buds of many plants in the subfamily Bamboo of Gramineae, and are formed by the buds on the underground stems of bamboo. The edible part of bamboo shoots accounts for about 27% of the fresh weight, and because of its low fat, high dietary fiber, rich in vitamins and other nutrients, bamboo shoots become a favorite food for consumers.

However, bamboo shoots have short harvest period and poor storage resistance, and are prone to dehydration and aging soon after harvest. Only 40% of bamboo shoots produced annually in China are used for fresh food and fresh sales, while the remaining 60% are used for processing. There are many processing methods for bamboo shoots, such as boiling, drying, canning and fermentation. Drying and dehydration is a common method in fruit and vegetable processing. At present, hot air drying, vacuum freeze drying and microwave drying are the main methods used for dehydration and drying of fruits and vegetables.

Drying technology is one of the most important preservation methods of bamboo shoots. With the development of society, people's demand for the quantity and quality of bamboo shoots is getting higher and higher. Traditional hot air drying can no longer meet the needs of people's lives. In bamboo shoot drying methods, in addition to hot air drying, there are vacuum freeze-drying, combined drying and so on.

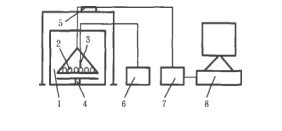

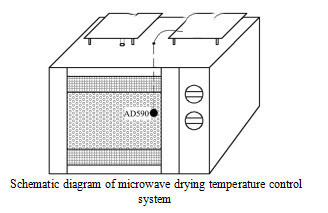

Compared with traditional drying, vacuum freeze-drying can keep the original shape of bamboo shoots and retain the nutrients of bamboo shoots to the maximum extent, but it has the shortcomings of long drying time and high energy consumption. Microwave drying bamboo shoots can be heated evenly, resulting in high quality products and short drying time. However, because constant power continuous drying is usually used, the drying process can not be controlled, and the quality of bamboo shoots is not easy to guarantee.

Combination drying, which adopts grading or staged combination drying, can synthesize the advantages of various drying methods and improve drying efficiency. Vacuum freezing combined with hot air drying method can maintain the quality of dried bamboo shoots and reduce production costs. The combined drying method of hot air and microwave reduces the drying time. In actual production, not only the drying rate of bamboo shoots is required to be fast, but also the quality of dried bamboo shoots must be guaranteed. Therefore, combined drying, which complements the advantages of different drying methods, will become the future trend of bamboo shoot drying technology.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply