- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Kinetics of Pepper

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Kinetics of Pepper

2018-12-24 10:05:30

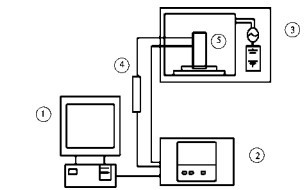

ABSTRACT: In order to understand the law of moisture change during microwave drying of hot pepper, the drying characteristics of hot pepper under different microwave power conditions were studied, and the microwave drying kinetics model was established. The results showed that the drying time of pepper decreased with the increase of hot air microwave power.

The microwave drying equipment of pepper can be divided into three stages: acceleration, constant speed and deceleration, and the water loss stage is mainly in the constant speed stage. In addition, the Page equation was found to be more suitable for microwave drying of pepper. The validation showed that the predicted value fitted well with the measured value. The model could accurately predict the moisture content in the drying process, which provided a theoretical basis for the control of the drying process of pepper.

Key words: pepper microwave drying; model

Pepper is a popular condiment, its value is not only in flavor, but also rich in capsaicin, VC and other nutrients.

Chili pepper has high medicinal value because of its phenolic compounds and other active substances. Therefore, the development space of chili pepper industry is very broad. Chili pepper is the first industry in vegetable industry in China. But capsicum is harvested in rainy season, so it is necessary to dry fresh Capsicum in time to avoid decay and mildew caused by long storage.

After effective drying, chili peppers are easy to store, pack and transport. It plays an important role in regulating the contradiction between weak and prosperous seasons and balanced supply in all seasons. Traditional drying methods usually adopt natural air drying and air drying, while traditional drying is easily limited. It not only has a long drying cycle, low efficiency, but also produces poor color and quality products.

The kinetic model can provide theoretical basis for predicting moisture content and controlling drying time of pepper in microwave drying process. It is a very important link in production to optimize drying kinetics and control the rate of material dehydration through the established mathematical model. Therefore, this paper studied the microwave drying characteristics of pepper, analyzed the influence of microwave power on the microwave drying of pepper and the law of microwave drying of pepper, which provided a theoretical basis for the microwave drying of pepper and the adjustment of equipment parameters.

Under other constant drying conditions, the effects of different microwave power on the drying characteristics of hot pepper were studied. The drying curve and drying rate curve of hot pepper were plotted. It was found that the size of microwave power had a great influence on the drying characteristics of hot pepper. With the increase of microwave power, the drying rate increased, while the drying time decreased. Less.

The whole microwave drying process of pepper can be divided into three stages: accelerated drying, constant-speed drying and slow-speed drying. The constant-speed and slow-speed drying stages are pepper micro-drying.

The main stage of wave drying process is that the initial moisture content of fresh pepper is relatively high and the microwave energy absorbed is more, so there will be a relatively short acceleration stage.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply