- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on the quality of green plum

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on the quality of green plum

2018-12-24 11:00:54

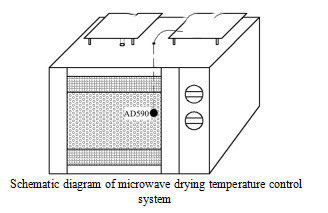

Abstract: The effects of four different drying methods, hot air drying, vacuum drying, microwave drying equipment and vacuum freeze drying, on sensory characteristics, main nutrient components and microstructure of green plum were studied.

Key words: green plum microwave drying; hot air drying; vacuum drying; vacuum freeze drying

Green plum, also known as fruit plum and sour plum, is an apricot plant of Rosaceae. It originated in China and was introduced to Europe. It has been cultivated for more than two thousand years in China. Green plum is famous for its acidity, the total acidity is about 4.62%~

6.78% of them are citric acid, the others are malic acid, succinic acid, acetic acid, lactic acid, citric acid, oxalic acid and so on. They have strong bacteriostatic activity, and inhibit the growth of 15 kinds of bacteria such as S. sobrinus and S. mitis.

Prunus mume is also rich in flavonoids, anthocyanins and other phenolic substances. It has good antioxidant activity and is a kind of food raw material with medicinal and food homology. At present, Chinese green plum is mainly exported to Japan and other areas or smoked into black plum for medicinal purposes, with very low added value, which makes it difficult to create higher economic value for fruit growers. On the other hand, green plum is easy to rot after harvesting because of its high moisture content, short storage period and easy to cause waste of resources. Therefore, turning green plum into dried fruit is an important way to prolong the shelf life of green plum.

After plucking, green plum should be dried and preserved for later processing and utilization. However, at present, the drying of green plum still stays in the traditional way of smoking. Maillard reaction and caramelization reaction in the process of smoking make the product dark brown, glossy and smoky, which is not suitable for further deep processing, and other drying methods of green plum have not been reported in the literature.

TIAN et al. considered that the nutritional composition, flavor substances, color, rehydration and structure of Lentinus edodes dried by vacuum microwave were superior to hot air drying and vacuum drying. JIANG et al. considered that the color, antioxidant composition and microstructure of vacuum freeze-drying Okra were better than hot air drying, but the drying time and energy consumption were relatively large.

Luo Dongsheng et al. studied the effects of different drying methods on the quality of jujube slices. The results showed that the rehydration, antioxidant content and aroma components of jujube slices were best maintained after vacuum freeze-drying and vacuum microwave drying, but hot air drying could improve the red value, volume density and relatively reduce the irritant odor of acetic acid. The purpose of this paper is to investigate the effects of different drying methods, such as hot air drying, vacuum drying, vacuum microwave drying and vacuum freeze drying, on moisture content, sensory properties, organic acids, total sugar, total phenols, total flavonoids content, color difference and microstructure of green plum, so as to provide basis for its drying, preservation and deep processing.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply