- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying methods on quality characteristics of black jujube powder

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying methods on quality characteristics of black jujube powder

2018-12-24 11:35:10

Abstract: jujube was used as raw material to prepare jujube powder by hot air, microwave drying equipment, spray, variable temperature pressure expansion and vacuum freezing. The physical properties such as wetting subsidence, dispersity, solubility and bulk density were studied. The comprehensive evaluation of 5 kinds of black jujube powder was calculated by coefficient of variation method, and the quality characteristics of dried jujube powder were explored by drying method. 5 methods were used to evaluate the quality of black jujube powder. To determine the best drying method of black jujube powder.

Key words: black jujube powder microwave drying; coefficient of variation weight method; comprehensive score; quality characteristics

Black jujube, also known as soft jujube and Junqianzi, is mainly divided into two categories: nucleated and seedless. Black jujube can improve human immunity, inhibit the growth and reproduction of cancer cells, promote the growth of white blood cells in vivo, reduce the content of serum cholesterol, and then improve serum albumin, protect human liver. Therefore, the nutritional value of black jujube is very rich, and it can be used as an ideal raw material for various health products and food research and development. In China, black jujube pulp has been used to reduce fever and promote endocrine in traditional medicine. It has obvious effect on tonifying kidney and nourishing stomach. It is called "nutrition warehouse".

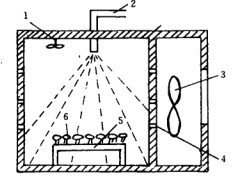

The drying technology of fruit and vegetable powder mainly consists of hot air, vacuum freezing, variable temperature pressure differential expansion, microwave and spray drying. Hot air drying is easy to operate and has low production cost, but its operation temperature is high, drying time is long and the product is prone to browning phenomenon. Vacuum freeze drying is a drying method operated under low temperature environment, which has the function of keeping the original bioactive substances of fruits and vegetables, but the operation time is long, the cost and energy consumption are high.

Extrusion drying technology with variable temperature and pressure difference is a new, environmentally friendly and energy-saving drying method for non-fried and expanded fruits and vegetables. Its drying efficiency is high, and most of the color, flavor and nutrition of fruits and vegetables are retained to a large extent. Microwave drying with three-dimensional heating method can quickly evaporate the moisture of fruits and vegetables and reduce the operation time, but it can cause local overheating of fruits and vegetables, which makes the products easier to produce. Large scale browning; spray drying technology has short drying time and fast speed, and is widely used in drying fruits and vegetables.

At present, there are few reports about drying products of black dates. Qiao Xiao congruent uses enzyme assisted spray drying to prepare black jujube powder, and optimizes the technology. The yield is 26.89%. Liu Chunhui and so on have studied the vacuum freeze drying technology for the preparation of black jujube stem. However, there is no report on the evaluation of the quality characteristics of black jujube powder prepared by different drying methods using coefficient of variation weight method.

In this experiment, black dates were selected as raw materials. Through the relative results of the pre test results and the drying of fruits and vegetables, 5 drying methods including hot air, vacuum freezing, temperature differential pressure expansion, microwave and spray were determined to prepare the jujube powder. According to the variation coefficient method, the weights of each index of the 5 different drying methods were calculated, and the experimental data were standardized. Finally, the weighted average method was used to calculate the comprehensive score of the black jujube powder prepared under five different drying methods, so as to determine the best drying method of the black jujube powder, and to provide theoretical basis for the development of high-quality instant black jujube powder parameters optimization and industrial production.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply