- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of drying technology of cherry tomato after osmotic pre-dehydration

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of drying technology of cherry tomato after osmotic pre-dehydration

2018-12-24 12:02:13

In this paper, the "Sulong 1" cherry tomato cultivars were used as test materials, and the effects of osmotic pre-dehydration on the drying characteristics and quality of cherry tomatoes were studied systematically, including hot air drying, microwave drying and vacuum drying.

The drying time of microwave drying equipment is short and the energy consumption is low, but the content of soluble sugar and lycopene after drying is significantly lower than that after hot air drying and vacuum drying. The content of soluble sugar and lycopene after vacuum drying is not significantly different from that of hot air drying, but the same drying effect is achieved by vacuum drying compared with hot air drying. It takes a long time to dry. The optimum drying method for cherry tomatoes after osmotic pre-dehydration was hot air drying at 60 C. Under this condition, the loss of nutrients was relatively small, the color was good and the energy consumption was low.

Key words: cherry tomato microwave drying; osmotic pre-dehydration; hot air drying; vacuum drying

Cherry tomato is a variety of tomato cultivated subspecies of Solanaceae, which originated in the tropics. Cherry tomatoes are richer in nutrition than ordinary large fruit tomatoes, and their vitamin content is 1.7 times that of ordinary large fruit tomatoes. FAO ranks them as one of the "four major fruits" to be promoted as a priority. The results showed that the fresh fruit of 100 g cherry tomato contained about 94 g of water, 2.51 g of reducing sugar, 0.6-1.2 g of protein, 20-30 mg of VC and 0.397 mg of beta-carotene. It also contained functional substances such as lycopene, glutathione, nicotinic acid, potassium, sodium, calcium, phosphorus, copper and iron, which were beneficial to human health. In addition, the cherry tomato peel contains rutin, which has the effect of lowering blood pressure and preventing arteriosclerosis.

Cherry tomatoes, besides fresh food, can also be processed into jam, preserved fruit, pudding, canned, dried fruit, fruit wine or muffin decoration, etc., which are more and more popular with consumers. When cherry tomatoes are dried, the semi-permeability of cell membranes can be used to transfer part of the water in the sample to the osmotic pre-dehydration process before drying, and then drying by a certain way can greatly shorten the dehydration time, improve the dehydration efficiency, reduce the sugar content of the product and improve the quality of the product.

Cherry tomatoes after osmotic pre-dehydration need further drying to obtain semi-dried products with certain water activity and moisture content. Different drying methods and conditions have different effects on the main nutrients and sensory quality of fruits and vegetables. The main drying methods of preserved cherry tomatoes are shade drying, vacuum drying, infrared drying and hot air drying.

ZHAO and other studies showed that compared with direct hot air drying, percolation pre-dehydration combined with hot air drying could shorten the drying time by 32.26%, reduce the color change by 18.11%, reduce the hardness by 88.21%, increase the volume ratio of products by 72.31%, and increase the preservation rate of VC by 125.82%. Li Hui et al. also found that osmotic preconditioning combined with hot air drying could shorten the drying time, and osmotic preconditioning combined with hot air drying could improve the sensory and nutritional quality of cherry tomatoes.

SHI et al. showed that osmotic pretreatment combined with vacuum drying could improve the color of tomato products and reduce the loss of nutrients such as lycopene. In addition, Tian Jianping's research shows that carrot chips with high drying rate and good quality can be obtained by the combined experiment of osmotic pre-dehydration and microwave drying. At present, the processing of cherry tomato by osmotic dehydration combined with other drying methods has been reported, but there is no systematic comparative analysis.

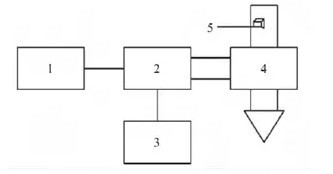

In this experiment, fresh cherry tomatoes were pretreated by osmotic dehydration, and the effects of hot air drying, microwave drying and vacuum drying on the drying characteristics and quality of cherry tomatoes were systematically investigated with drying time, water activity, soluble sugar content, lycopene content, color and energy consumption as the evaluation indexes, so as to determine the best drying method and conditions.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply