- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Vacuum Pulsation Drying Characteristics and Drying Quality of Lotus Pollen

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Vacuum Pulsation Drying Characteristics and Drying Quality of Lotus Pollen

2018-12-24 16:55:14

Absrtact: In order to shorten the drying time of pollen and ensure the drying quality, vacuum pulsation drying technology was applied to drying fresh lotus pollen. The effects of vacuum holding time (15, 12, 9, 6 and 3 min), drying temperature (45, 50, 55, 60 and 65 C) on drying kinetics, water effective diffusion coefficient and drying activation energy were studied, and Weibull distribution function was used to simulate the drying process. In addition, the effects of vacuum holding time and drying temperature on protein content and microstructures of pollen were studied, and the color difference of pollen before and after drying was analyzed.

Key words: pollen microwave drying; kinetics; quality control; vacuum pulsating drying; microstructure

Pollen is rich in nutrients, such as proteins, lipids, flavonoids, vitamins and polysaccharides and other bioactive substances. It plays an important role in human nutrition and health. It is a veritable "micro nutrient bank".

Pollen has a variety of biological activities and nutritional and health benefits are closely related to its rich nutritional components. However, due to the high moisture content of fresh pollen (usually 30%-40%), it is easy to occur bulk, mildew, fermentation and deterioration during storage and transportation, resulting in loss of nutrients and reduced health effects.

Therefore, it is an urgent problem in pollen processing to choose a scientific and reasonable drying method to reduce pollen moisture content (5% to prevent pollen mildew and deterioration), prolong shelf life, and retain its nutritional and functional components to the maximum extent.

At present, the main drying methods of pollen at home and abroad are sun drying, hot air drying, vacuum freeze drying and microwave drying. Solar drying is a traditional method of pollen drying. It has many problems, such as long drying time, susceptible to weather changes, susceptible to pollution in drying process, more loss of pollen nutrients, and difficult to reduce pollen moisture content to less than 5%.

Hot air drying equipment is simple and efficient, but hot air drying can easily lead to inconsistency of moisture inside and outside the material, and the color of the material is easy to deteriorate due to oxidation during drying process. Vacuum freeze-drying can effectively reduce the loss of color, aroma, taste and nutrients of materials, but it is difficult to popularize vacuum freeze-drying equipment in large scale because of its high price, high energy consumption in drying process and long drying time.

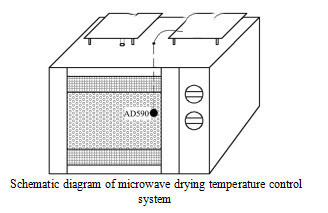

As a widely used drying technology at present, microwave drying equipment mainly focuses on the drying of raw materials such as fruits and vegetables, and its drying rate is high. Liu Jiayin and others used microwave drying technology to dry lotus pollen. The results showed that although the microwave drying efficiency was high, the color of lotus pollen became worse after drying, and the drying process had a greater impact on the catalase activity of lotus pollen. Therefore, exploring new drying technology and process of pollen to improve drying efficiency and quality is of great significance to promote the development of pollen drying industry.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply