- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Process optimization of microwave drying of purple sweet potato powder

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Process optimization of microwave drying of purple sweet potato powder

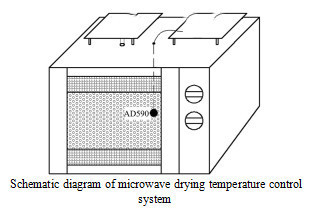

2018-12-28 15:18:41The composition of colour-protecting solution, colour-protecting time and the effects of microwave drying and hot air drying on purple sweet potato powder were discussed.

The optimum technological parameters are as follows: the color-protecting liquid is composed of 0.8% salt, 0.6% citric acid and 0.4% ascorbic acid. The color-protecting time is 6 minutes, and the microwave drying time is about 10 minutes. Microwave drying equipment can effectively retain the flavor and nutritional components of purple sweet potato, and improve the quality of purple sweet potato powder.

Key words: Purple sweet potato powder microwave drying; color protection; color difference value;

Purple sweet potato originated in southern Kyushu, Japan. It was introduced into China in 1990s and successfully planted. Purple sweet potato is rich in dietary fiber, minerals and vitamins, and has the health function of cancer prevention and anti-cancer. Purple sweet potato is rich in purple anthocyanin, which has special use and nutritional value.

Studies have proved that purple pigments have a strong function of removing oxygen free radicals, can delay aging, and can be used to develop health food and functional food. With the development of science and technology, purple sweet potato, a kind of food material integrating nutrition and health care, is becoming more and more popular and concerned by people.

Hot air drying is widely used in large-scale production of food processing because of its low energy consumption, simple production method, low investment and high yield. But the cells of purple sweet potato powder produced by hot air drying are easy to be destroyed during hot air drying, resulting in poor rehydration of the product, resulting in changes in color, structure, flavor and nutritional value of the product.

The microwave heating from the inside of the material forms a temperature gradient which decreases from the inside to the outside, and the moisture gradually dissipates from the inside of the material from the inside to the outside, so as to achieve the purpose of drying, which can better retain the nutrients in purple sweet potato.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply