- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of drying methods on quality and antioxidant capacity of okra flower tea in vitro

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of drying methods on quality and antioxidant capacity of okra flower tea in vitro

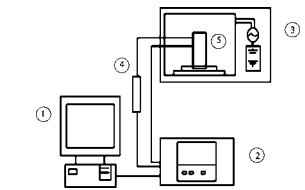

2018-12-29 09:46:40ABSTRACT: In order to study the effects of different drying methods on the quality and in vitro antioxidant capacity of okra flower tea, the okra flower was treated by 50 ~C hot air drying, 70 ~C hot air drying, microwave drying equipment and vacuum freeze drying. The appearance quality, color, polysaccharide content, flavonoid content, antioxidant capacity and sensory quality of okra flower tea were analyzed.

The results showed that there was no significant difference in appearance quality and antioxidant capacity between Okra tea and tea dried by 50 ~C hot air drying and 70 ~C hot air drying (P > 0.05), but there was slight difference in polysaccharide and flavonoid content. The okra tea dried by microwave drying had severe shrinkage in appearance, burnt paste in interior and exterior, but strong aroma and high antioxidant capacity in vacuum freeze-drying place. Li's okra flower tea has symmetrical appearance and bright color. The content of polysaccharides and flavonoids in flower tea and flower tea water is the highest, and the antioxidant ability is the highest. The color of flower tea water is golden and transparent, and the flavor is pure, but the fragrance is mild. The results provide technical guidance for comprehensive utilization and processing quality control of okra tea.

Key words: okra tea microwave drying; drying method; quality; in vitro antioxidant capacity

Okra, also known as coffee sunflower, kidney-tonifying herb, capsicum, carob, etc., is an annual herb of the genus Malvaceae. Originated in Africa, it is planted all over the world, especially in Africa, the United States and Japan. There are also distribution and cultivation of Okra in many parts of China, mainly in Jiangsu, Fujian, Zhejiang, Guangdong, Hainan and other places.

With the special edible and medicinal effects being known and understood by people, okra has gradually developed into a new and characteristic vegetable with great potential, and the cultivation area of okra is also expanding rapidly.

Because the growth period of okra is very short, the period from pod formation to young pod harvesting is only about 2 days. Each pod will accompany the growth of a flower. Every flower from blooming to withering is only about 10 hours. Generally, it is only allowed to blossom and fall on its own without collection and utilization. The yield of abandoned flowers is about 7.5 x 105 per hm2, which results in a great waste in production and is a waste to agriculture. The village environment has also caused a certain degree of pollution. Therefore, the comprehensive utilization of okra is of great significance to the development of okra industry.

Okra flower was used as health tea and herbal medicine hundreds of years ago. It is rich in polysaccharides, flavonoids, zinc, selenium and other bioactive substances. The viscous polysaccharide contained in Okra flower is a covalent complex of polysaccharides and proteins composed of arabinose, galactose, rhamnose, etc. It has the functions of digestion, immunity enhancement, anti-cancer, blood lipid reduction and so on. Flavonoids have the functions of reducing lipid, anti-cardiovascular disease, eliminating free radicals and anti-oxidation, anti-osteoporosis, anti-cancer and so on.

The research on okra flower mainly focused on the extraction of polysaccharides and flavonoids and the antioxidant capacity. Liu Xiaoxia optimized the extraction process of okra flower polysaccharides by response surface analysis, separated and purified the polysaccharides, analyzed the monosaccharide composition and molecular structure of okra flower polysaccharides; Song Siyuan et al. optimized the extraction process of okra flower polysaccharides by ultrasound-assisted extraction method. Art, analysis found that the extract of okra polysaccharides had good antioxidant activity in vitro; Hu Shuai and other four extraction methods were compared to extract the total flavonoids in okra, found that the water bath ultrasonic extraction method was the best.

At present, the market of okra flower tea is dim in color, fragrance is insufficient, functional factors and health effects of flower tea are not clear, and drying methods play a vital role in the quality of okra flower tea. The effects of four drying methods on the quality of okra flower tea, functional factors in flower tea and tea water and their in vitro antioxidant capacity were compared. The advantages of different drying methods in the processing technology of okra flower tea were analyzed to provide basis for the quality improvement and control of okra flower tea.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply