- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on drying characteristics and quality of Polygonatum sibiricum

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on drying characteristics and quality of Polygonatum sibiricum

2019-01-02 11:22:57

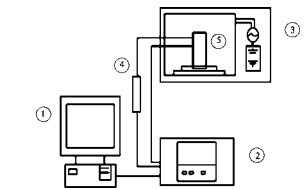

Absrtact: The effects of microwave vacuum drying, natural sun drying, microwave drying equipment, vacuum drying and hot air drying on the drying curve, polysaccharides, total phenols, total saponins, 5-carboxymethyl furfural content and antioxidant activity of Polygonatum were studied.

Polysaccharides, phenols, saponins and 5-hydroxymethyl furfural in Polygonatum sibiricum were extracted by ultrasound-assisted method, and their contents were determined by the methods introduced in the literature.

At the same time, the antioxidant activity of Polygonatum Polygonatum polysaccharide was detected by FRAP and superoxide anion free radical assay. The results showed that microwave vacuum drying had the highest drying rate and the shortest drying time. The loss of polysaccharides, total phenols and total saponins was the least. The production of 5-carboxymethyl furfural was small. The polysaccharide content of Polygonatum sibiricum in the dried product was 63.59 (+1.25) mg.g-1, and the inhibition rate of 20 mg.mL-1 polysaccharide solution on superoxide anion free radicals was 30.01 (+1.3). 0%). It is concluded that microwave vacuum drying method is more suitable for obtaining high quality xanthate dried products.

Key words: microwave drying polygonatum, drying curve, Polygonatum polysaccharide, antioxidant activity

Polygonatum sibiricum is a perennial herb, which has the health-preserving effect of enriching qi and nourishing and strengthening the body. Since ancient times, Polygonatum sibiricum has been widely used in people's daily life as a medicinal material, boiled into soup for the treatment of various diseases, or as a food material, cooked into a medicinal diet with special efficacy.

Polygonatum polysaccharide is the most abundant active ingredient in Polygonatum, which has anti-aging, anti-cancer, hypoglycemia and lipid, anti-atherosclerosis, diabetes and other pharmacological effects. In addition, phenolic compounds and saponins are the active ingredients of polygonatum.

So far, the natural drying method is mainly used in the processing of Polygonatum sibiricum. Influenced by the weather and air-drying conditions, the quality of the dried product of Polygonatum sibiricum by this method is not high. It not only has the problems of easy mildew and moth, but also has the problems of heavy loss of active ingredients caused by too long air-drying time. In order to reduce the loss of active ingredients, it is necessary to explore new drying methods of polygonatum.

However, literature shows that with the prolongation of drying and processing time, 5-hydroxymethyl furfural (5-HMF) and other harmful substances will be produced in Polygonatum, and excessive intake of 5-HMF will cause adverse effects on human liver and kidney.

In this paper, the effects of microwave vacuum drying, natural sun drying, microwave drying, vacuum drying and hot air drying on the contents of polysaccharides, phenolic compounds, saponins, 5-hydroxymethyl furfural and the activity of polysaccharides were compared to provide experimental basis for obtaining high-quality drying methods of polygonatum.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply